AR Coated Lenses

Overview

Features

Suitable for multi-kW, intracavity and ultrafast applications.

IBS coated and optimized for high laser power applications.

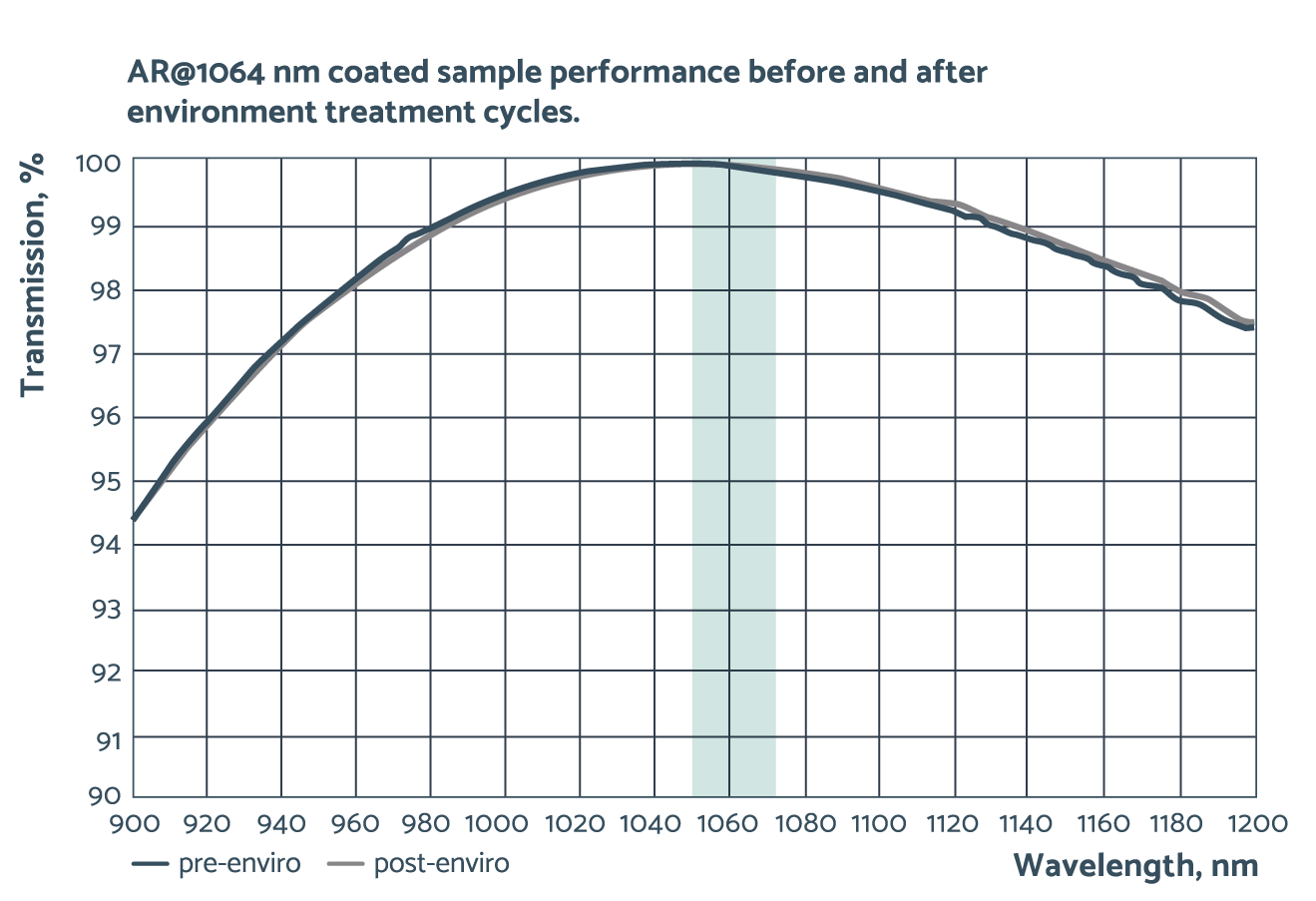

Reflectance per surface down to R<0.01%.

Sputtered anti-reflective coatings feature performance close to theorectical.

High Damage Threshold

AR coatings have laser induded damage threshold in range of 58 J/cm2, 1064 nm, 10 ns, 10^3-on-1.

Absorption loss <1 ppm per coated surface @ 1064 nm.

Absorption is the main damage and fatigue driver. With absorption being at low level, AR coated lenses feature enhanced duty cycle.

Thermal shift free performance, negligible fatigue of coated surface.

Durable, non-porous and near bulk coatings.

Custom

Custom - (Bi)Convex, (Bi)Concave, meniscus shapes and cylindrical lenses.

- Sapphire, YAG as a substrate material for mid-IR applications.

- High purity FS optimized for wavelength range. Bulk absorption down to 1 ppm/cm.

- Diameter from 3 mm up to 360 mm.

- Single wavelength, multiwavelength and broadband configuration.

- Spectral range from 200 nm up to 5000 nm.

What is so special about AR coated components from OPTOMAN?

IBS AR coatings are extremely durable and environmentally stable due to the density of layers. Incredible resistance makes them

perfect for on-field applications.

Low loss configuration allows transmittance higher than 99.98% of AR/AR coated components and absorption lower than 0.3 ppm @ 1064 nm, for example.

Typical commercial AR coatings feature residual reflectance below 0.25% per surface. 0.1% is becoming quite a common value as well. In any case, imagine having a laser beam with 1 kW power passing through such a component. Transmittance loss is ~2 W – 5 W and this light goes somewhere back to the laser system…

With the low loss coating technology, OPTOMAN can reduce this number down to 0.2 W, because residual reflectance per coated surface can go below 0.01%.

Damage threshold > 40 J/cm2 @ 1064 nm, 10 ns, 103–on–1.