Ion Beam Sputtering (IBS)

Ion Beam Sputtering (IBS) or Ion Beam Deposition (IBD) is a Physical Vapour Deposition (PVD) technique in which the layer of a desired material is formed by molecules extracted from the target material by a highly energetic and precisely controlled ion beam.

The key principle lies in the mechanism of extracting molecules from the target material. The possibility of material sputtering is enabled by ion grid optics, which can precisely control ion energy and beam focus. When the proper ion energy is chosen to minimize ion implantation (typically 1000-2000eV), the ions are precisely directed to the target material, and the desired atoms or molecules are knocked out of their stable positions by multiple collisions and can leave the target. Such interaction between the ion beam and the target is called sputtering.

Utilizing this, an optical interference coating is created by stacking layers of different materials and precisely controlling the thickness of each layer. Coatings produced by the Ion Beam Sputtering technology are proven to meet the most demanding industry and scientific requirements and provide numerous benefits for laser and laser systems manufacturers.

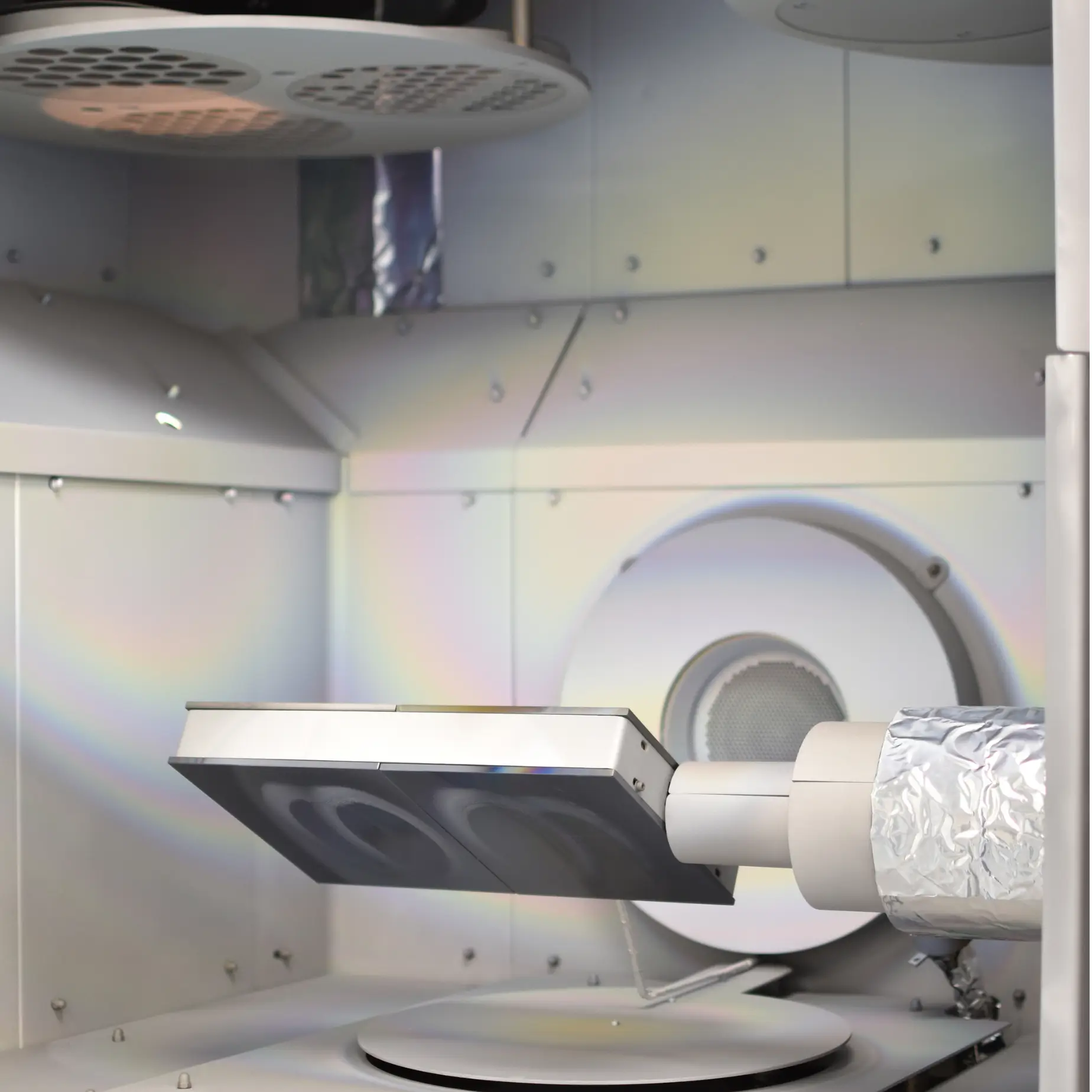

Ion Beam Sputtering (IBS) Family

OPTOMAN employs 5 IBS machines to ensure the best fit for each coating run.

Send us a

message!

Relax and build your laser. OPTOMAN

has your back.

Thank you

for your request

We will contact you as soon as possible