Whitepapers

Large Diameter Optics

Large-diameter optics are essential components in some of the most advanced and demanding optical systems — from imaging systems in astronomical telescopes and ultrashort pulse compressors to inertial confinement fusion systems, large-scale interferometers, and directed energy laser weapons. This tech note covers the key factors to consider when choosing and using large optics in demanding laser setups.

IBS Coated Silicon Carbide Optics

Silicon carbide (SiC) is favored for laser mirrors in space and defense applications due to its light weight, high thermal conductivity, and mechanical robustness. Learn more about OPTOMAN IBS Coated SiC Mirrors in the following tech note.

Non-degrading ultrafast optics

Building on the success of Non-Degrading UV Optics, OPTOMAN introduces Non-Degrading Mirrors for Ti:Sa lasers and OPCPA laser systems, offering broadband coverage with no color change — ensuring uptime and reducing maintenance costs.

Non-Degrading UV Mirrors

It’s easy to assume that having the highest possible LIDT guarantees the suitability of laser optics for a high-power system. However, the UV part of the spectrum poses significant threats to laser optics, causing fatigue in the coating and leading to degradation and color change. OPTOMAN has a solution – learn more in this tech note.

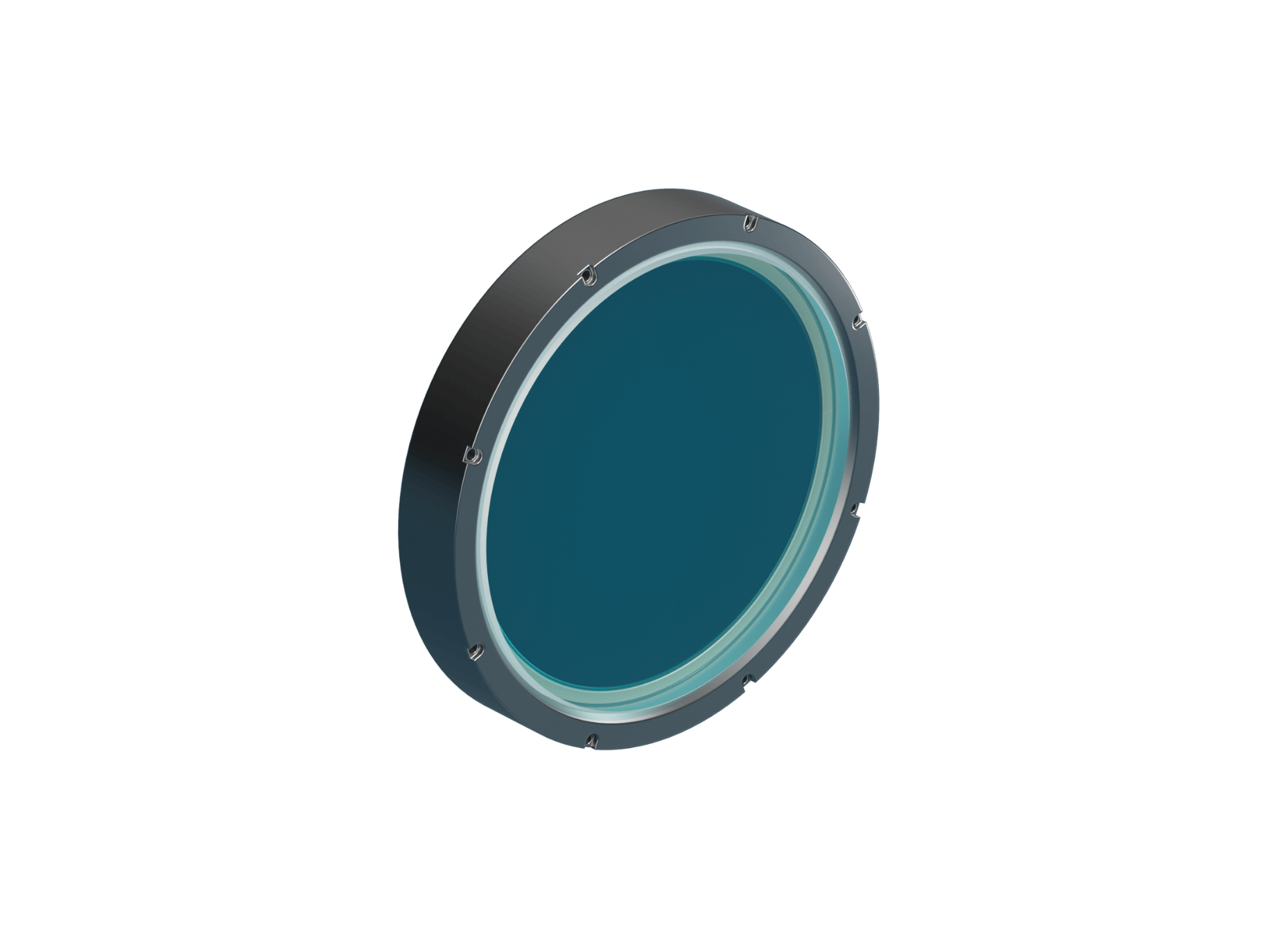

Low Absorption Protective Windows

Low Absorption Protective Windows are widely used in laser processing to ensure high transmission of laser energy, protect laser system, and minimize thermal effects. Find out how OPTOMAN handles it in this tech note.

Low Absorption Chirped Mirrors

Absorption in chirped mirrors can cause thermal lensing, which is not ideal and can lead to several problems. This will not happen with OPTOMAN new Chirped mirrors that feature 5 times lower absorption than market standard chirped mirrors. Find out more in this tech note.

High power laser mirrors for PW and TW lasers

The pinnacle of peak powers – TW and PW lasers – enable various applications, including material processing, fusion, and ultrafast processes in physics. But this sometimes comes at the cost of a headache for coating engineers, especially when designing high-power laser mirrors that can withstand extreme intensities. In this tech note, learn how OPTOMAN avoids that and deals with extreme powers.

Laser Optics for Surgical Applications

Using lasers for surgeries grants great benefits, however it also induces problems in terms of laser optics. Find out how OPTOMAN faces and solves them in this tech note.

Laser Optics for Aesthetic applications

As laser technologies become more and more prominent in aesthetic applications, laser optics manufacturers face new challenges. Find out how OPTOMAN accommodates to the rising demand.

The Optical Challenges of Laser Space Communication

Data transmission in space using lasers comes with a great deal of benefits. However, challenges for coaters become even more prominent…

Mirrors for Multipass Cells (MPC)

As the market demand for higher pulse energies at pulse durations below 50 fs increases, OPTOMAN views Multipass Cells as a prominent member of the photonics family. But why?

Mid-IR Dispersive Mirrors

As ultrafast applications in the mid-IR spectral range are getting more and more attention, OPTOMAN has developed dispersive mirrors in this region to help you compress your pulses even further! Make those pulses ULTRAfast!

Mid-IR Capabilities

Mid-IR holds quite a significance in various applications. However, it is not common to manufacture Mid-IR laser optics with Ion Beam Sputtering technology. But OPTOMAN does it!? Find out why and how in this tech note.

Ion Beam Sputtering (IBS) coated laser optics

OPTOMAN aims for the highest possible accuracy, repeatability and quality by exploiting the most advanced thin film deposition technology

Repeatability capabilities

Precision, consistency, and repeatability are key factors in every industry, including photonics. At OPTOMAN, we understand that your laser system’s performance depends on the reliability of laser optics. That’s why we don’t just promise high-quality optics, we deliver consistency and peace of mind.

Why Ultrafast Lasers are so Ultrafast in Damaging Optics?

Since any laser, no matter how powerful and fast it may be, is only as strong as its weakest link, ultrafast optics and the reasons behind their damages must be addressed strategically.