Low Absorption Chirped Mirrors

To shorten the pulse duration in high-power ultrafast laser systems, pulse compression is necessary. For this, pulse compression mirrors are used. Chromatic dispersion, induced by varying the thickness of dielectric coating layers, enables controlled Group Delay Dispersion (GDD), which consequently enables pulse compression. Nevertheless, controlling the heat accumulated in standard chirped mirrors due to absorption remains a problem. This heat creates a refractive index gradient, leading to thermal lensing—a distortion caused by uneven heating. As a result, the beam focus is altered and unwanted drifts occur. Moreover, absorption is the primary driver of coating degradation, which significantly lowers the lifetime of laser optics.

OPTOMAN, through extensive R&D, developed low-absorption chirped mirrors to address these challenges. By reducing absorption by approximately a factor of 5, these mirrors minimise heat generation, hence ignoring the effects of thermal lensing. This innovation ensures stable beam focus and that no unwanted drifts occur.

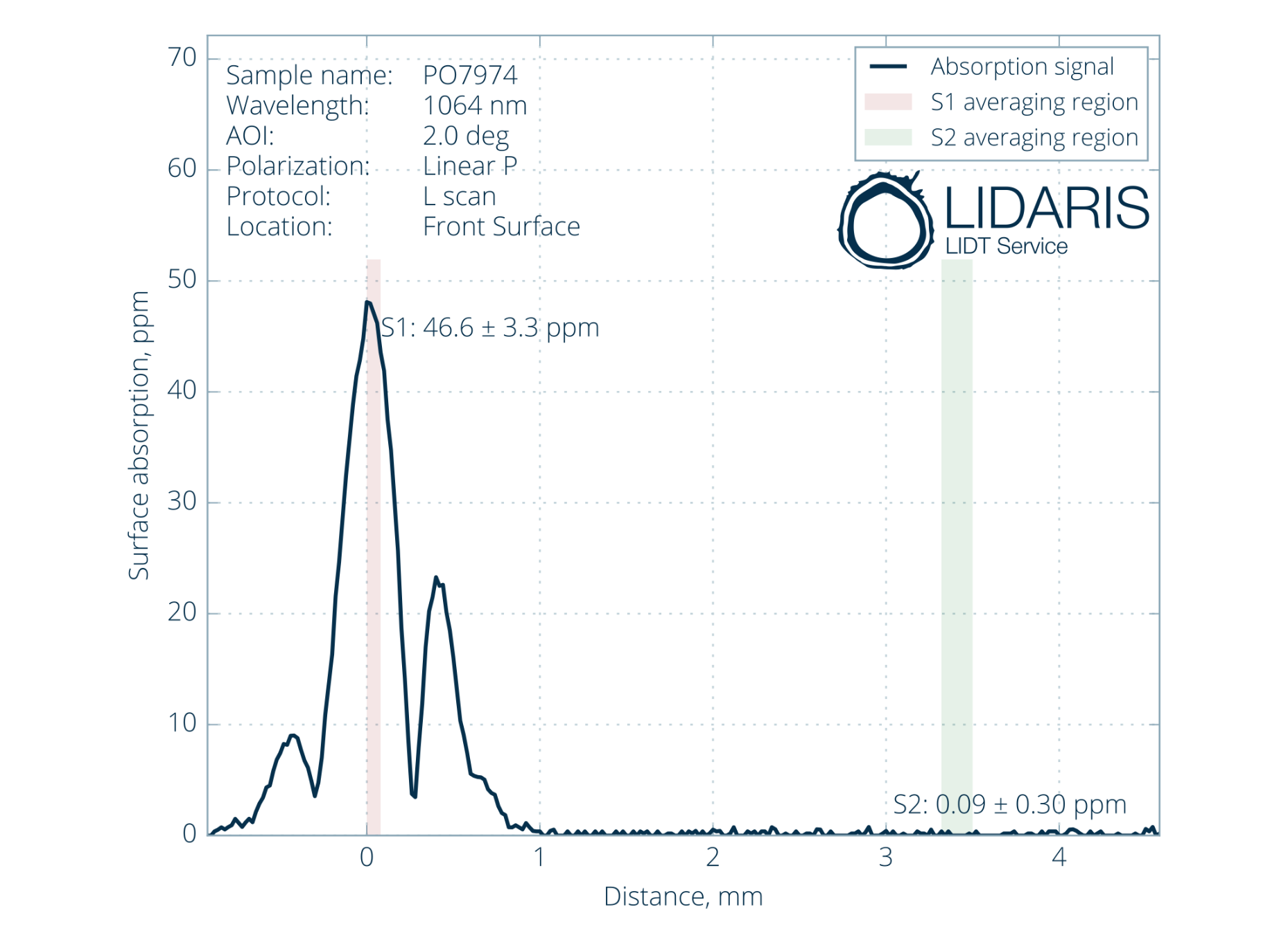

The before

Typical market-standard absorption of chirped mirrors.

Absorption measurement – 46.6 ± 3.3 ppm.

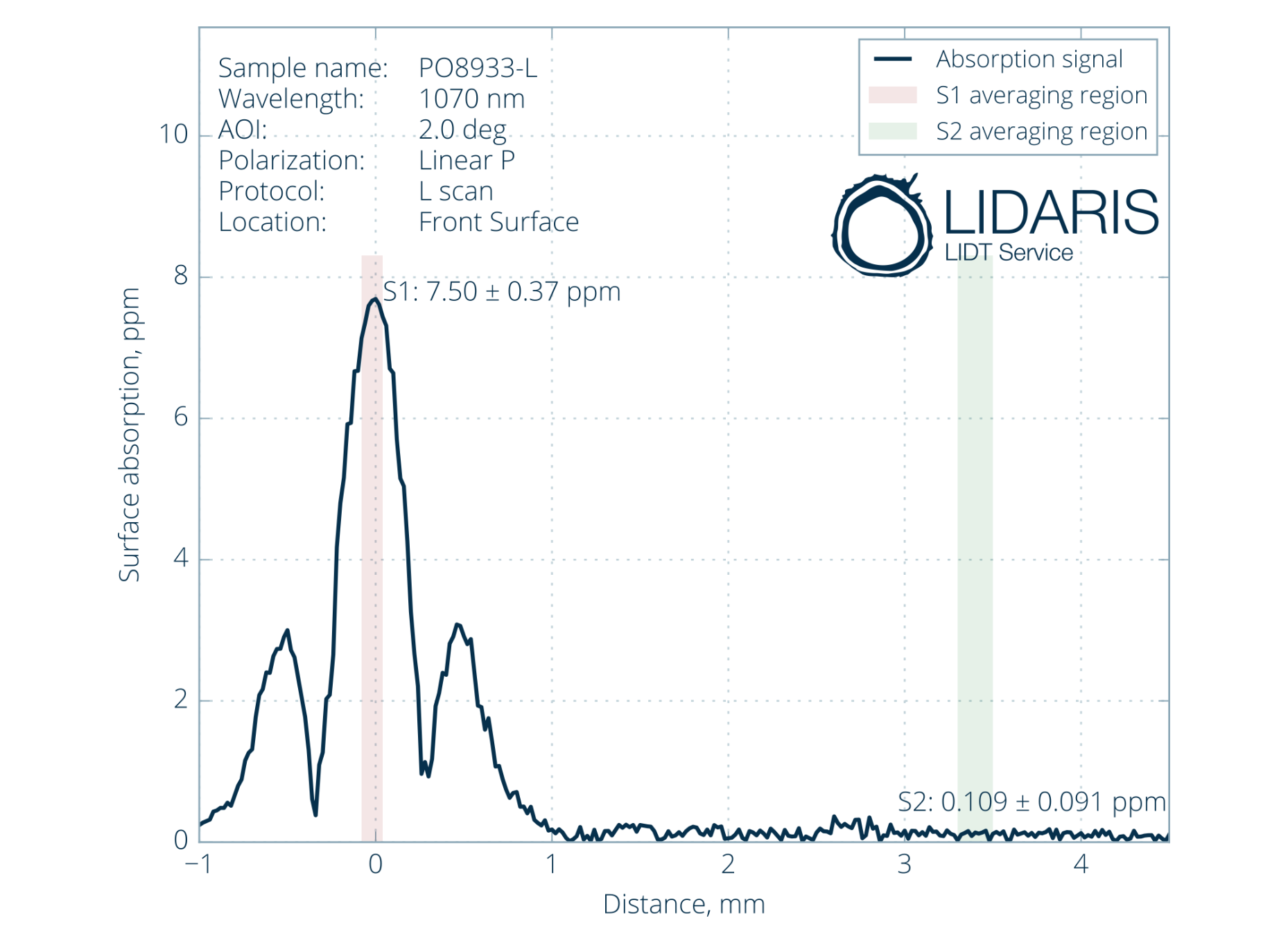

The after

OPTOMAN Chirped mirrors absorption after extensive R&D efforts.

Absorption measurement – 7.5 ± 0.37 ppm

The graphs clearly showcase the considerable reduction in absorption. Due to these advancements, OPTOMAN chirped mirrors guarantee thermal lensing wouldn’t be a burden, making them ideal for high-power applications.