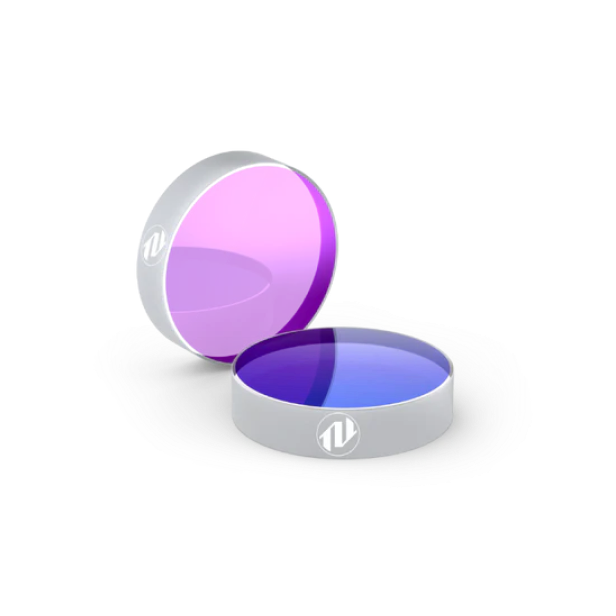

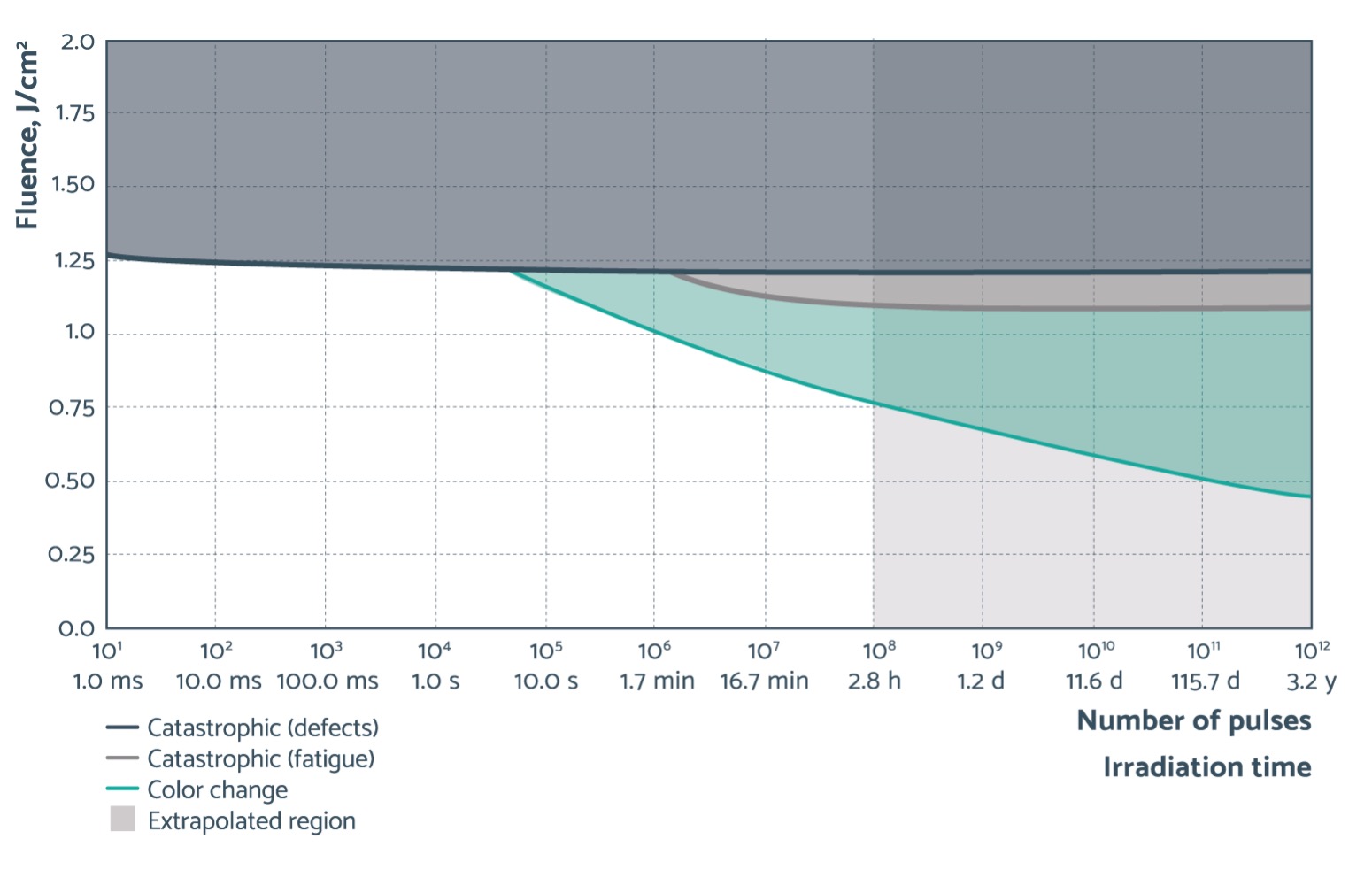

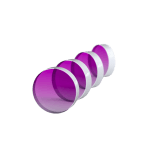

Unlike current components that degrade over time, our new Non-degrading UV Optics are designed to withstand prolonged exposure to high power laser pulses, enabling these systems to operate for more than 10,000 hours, which directly translates into lower maintenance costs, reduced downtime, and longer overall lifespan for high-power laser systems, which are crucial for industries that rely on continuous, high-precision operations.

- No color-change effect

- Enhanced lifetime (over 10000h)

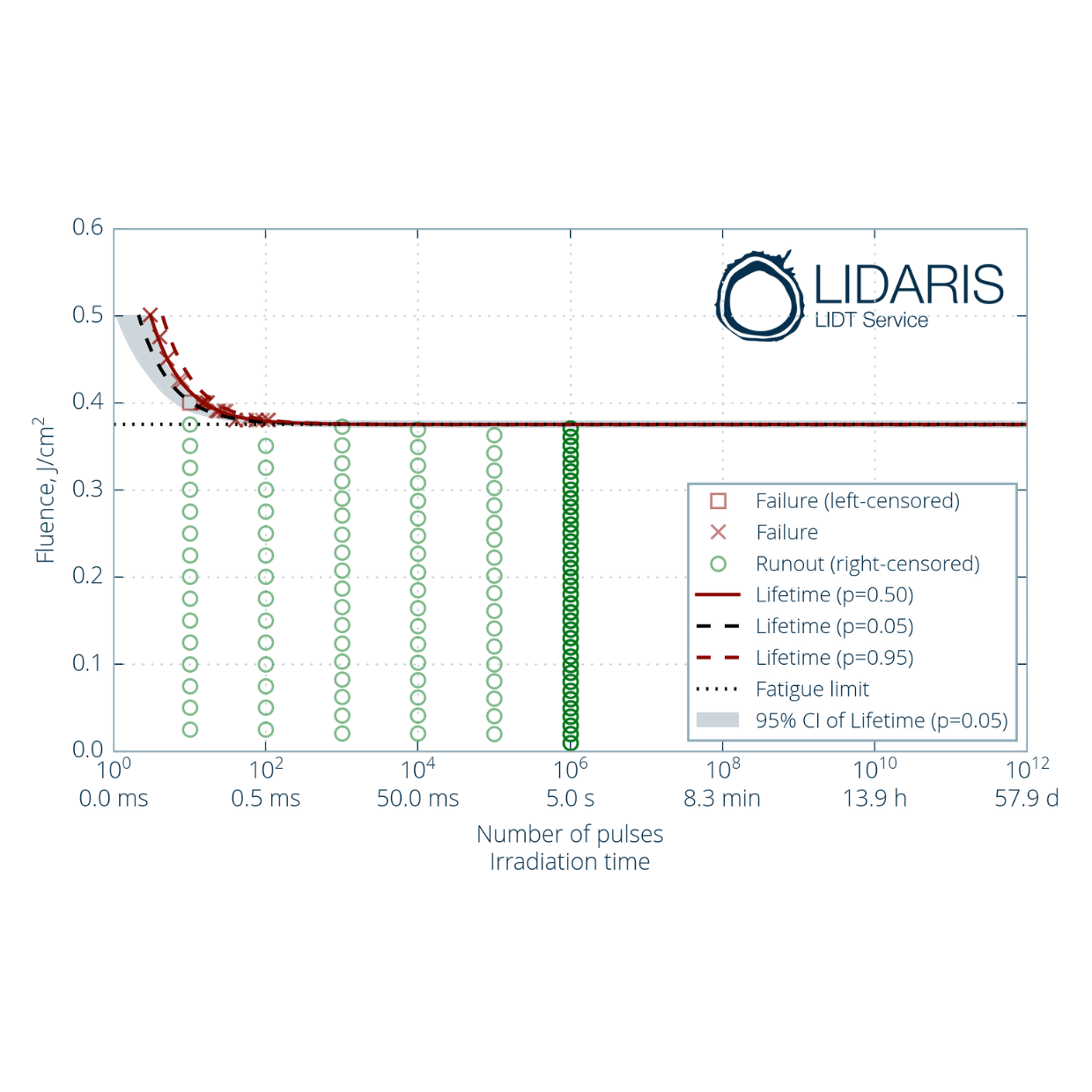

- Higher LIDT (>0.35 J/cm² @ 343 nm, 300fs)