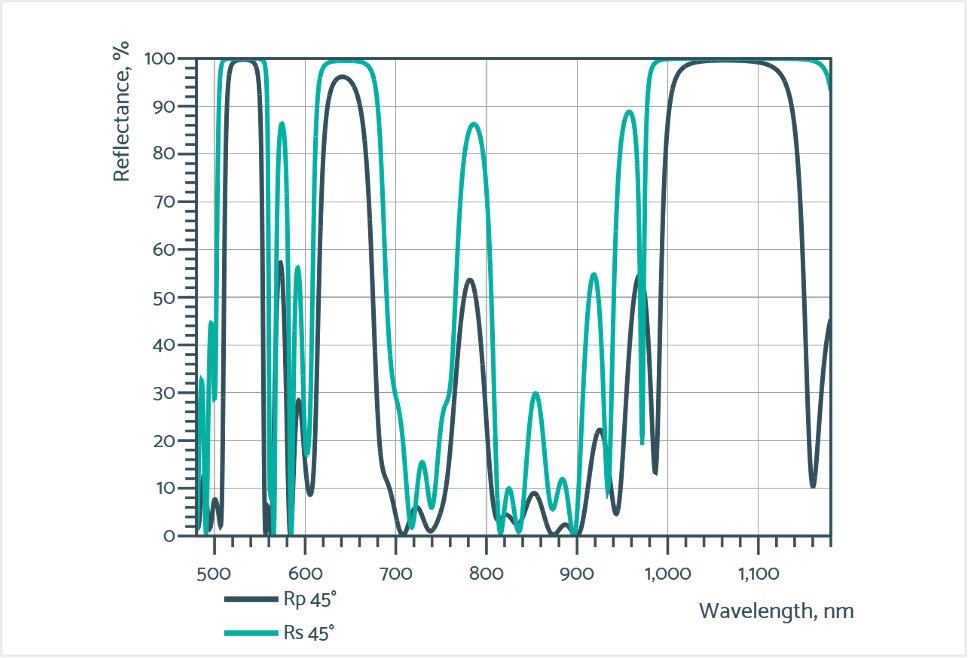

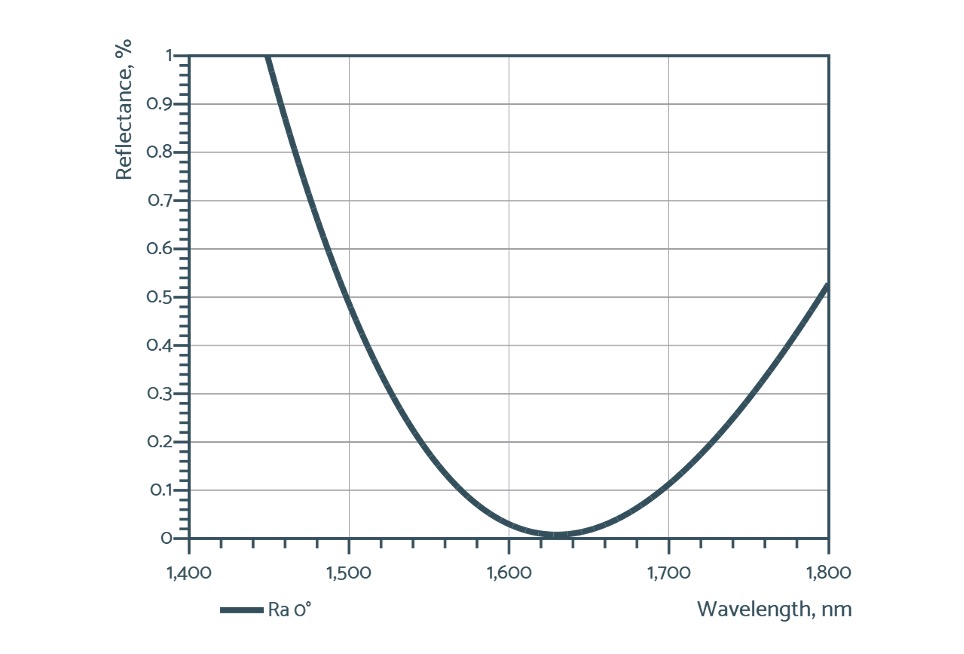

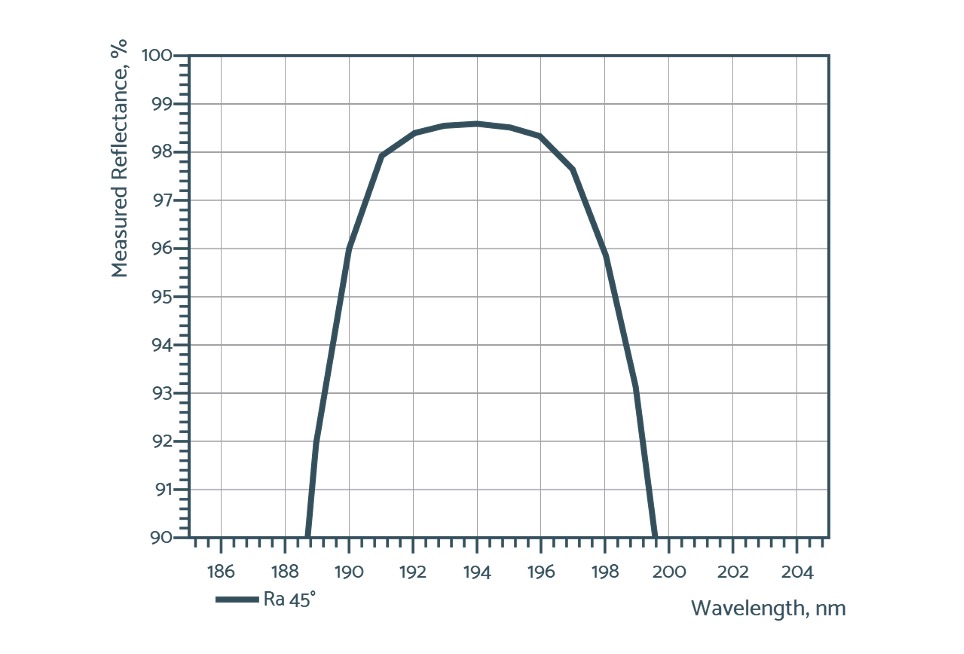

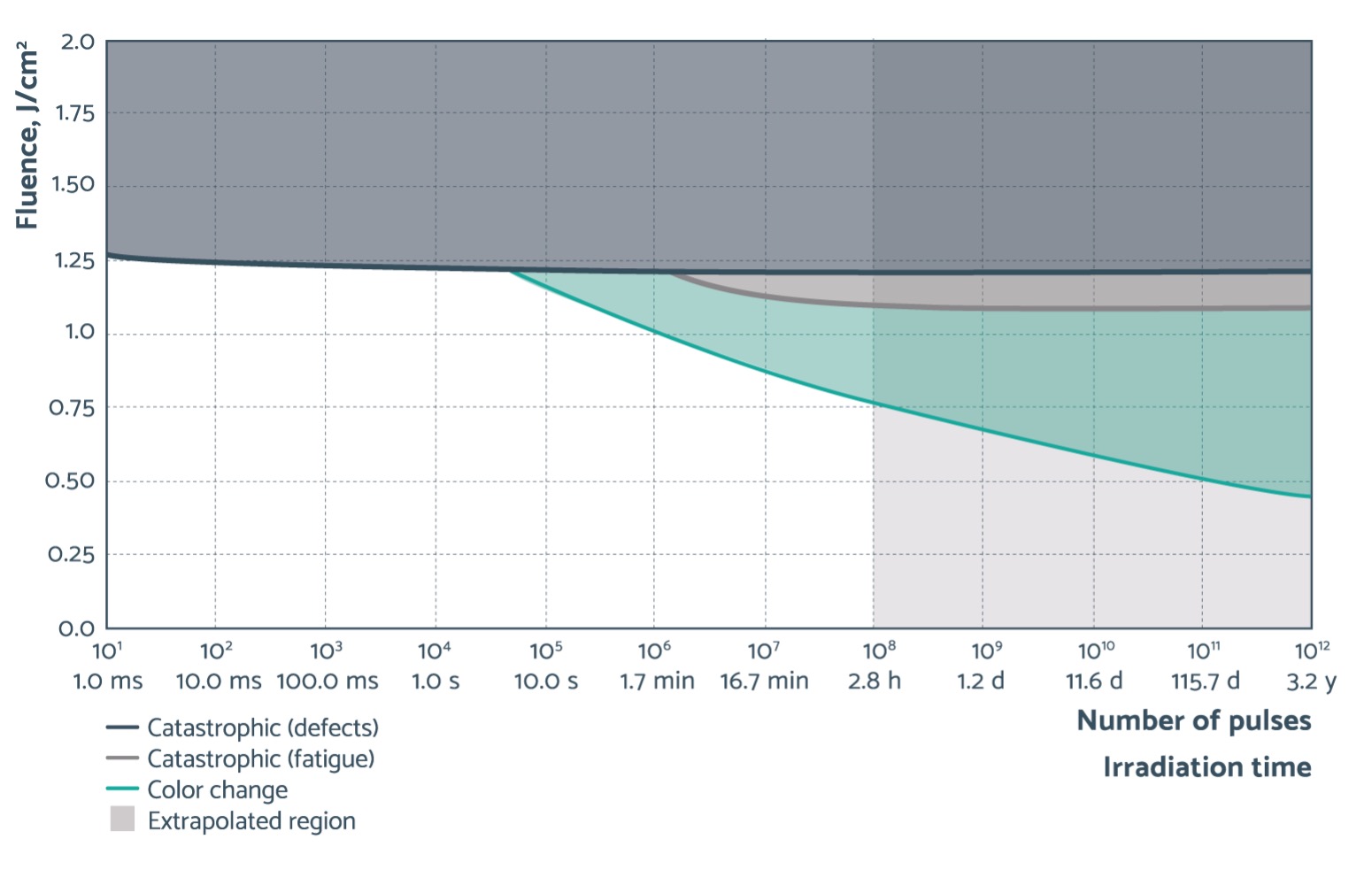

Combining different wavelengths and maintaining high spectral performance requires extensive expertise in optimizing coating design. This includes polarization-specific coating tuning and some creativity with material selection to ensure high LIDT at different wavelengths.

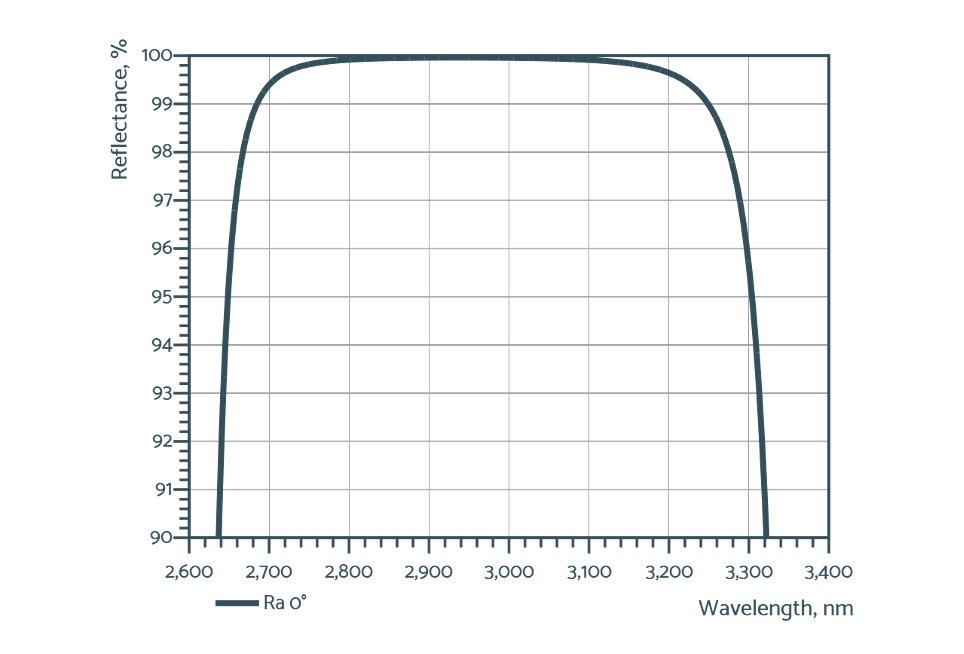

OPTOMAN multiwavelength mirrors allow for low accumulated transport losses. For example, the market standard 7 mirror articulated arm has around 85-95% transport efficiency — with our solution, customers can be in the 97-99% zone.

- Low accumulated transport losses

- Phase-shift optimization to maintain polarization

- High LIDT (>168 J/cm² @ 1064 nm, 9.8 ns,223 μm).