The Optical Challenges of Laser Space Communication

In recent years, the laser has emerged as a crucial technology when it comes to data transmission in space, thanks to its ability to enable secure and super-fast communication on Earth from outer space via satellite or between satellites themselves, allowing more data to be transferred in less time.

However, this relatively new type of optical communication still faces its share of challenges. This tech note highlights the importance of laser optics and selecting the right strategic supplier sidekick to ensure that space communication systems remain powerful and reliable for years to come.

A quantum leap in space communication

So why lasers?

- Data rates of the speed of light. Laser light carries information at 10-100 times higher rates compared to radio signals. This makes it possible to send massive volumes of data from deep space missions and orbiting satellites more quickly.

- Iron-clad security. The laser’s focused beam can act as a shield against interception or jamming, making it a great choice for secure communication.

- Energy efficiency. Laser-based systems are energy-efficient, as the focused beams of the laser can minimize the power waste caused by spreading or absorption, in turn, helping to reduce the energy footprint of communications equipment.

- Super low-latency. Laser communication can also benefit from reduced latency, making it ideally placed for real-time applications such as remote spacecraft control.

What are the challenges?

The journey of laser optics in laser space communication can be long, with plenty of obstacles along the way for engineers. The extreme conditions of space, including radiation, temperature swings, and the unforgiving vacuum, could potentially cut short the lifetime of traditional optics. This can leave space communications vulnerable, with frequent replacements that are both costly and logistically almost impossible.

In the vast expanse of space, maintenance is a particular challenge, with repairs and replacements like embarking on a costly quest to the unknown. Reducing maintenance requirements at the design stage is key to ensuring that the world remains connected.

The high total cost of ownership (TCO) is another possible asteroid field for space communications projects. Short optical lifetimes and the need for constant maintenance will only add to this cost, which could negatively impact the feasibility of future missions. Reducing TCO is crucial in ensuring that space communication remains economically viable.

Reliability can also be a challenge. Optical components are critical for signal transmission, so low reliability could spell disaster. A space communication network’s success hinges on the dependability of its laser optics, so it’s important to partner with a sidekick who can help improve that all-important optical reliability.

OPTOMAN: The cosmic guardian of optics

OPTOMAN is your sidekick when it comes to supplying laser optics for space applications.

Born in Vilnius, Lithuania, OPTOMAN is a coatings superhero, who designs, develops and manufactures advanced, high accuracy and repeatability thin film coatings by Ion-beam sputtering (IBS) technology.

Ion-beam Sputtering technology

Note that just ion beam sputtering technology and choice of coating materials is not enough for top-notch optics production. Expertise plays a critical role and OPTOMAN is well suited for this. Investments in research and development and ability to make coating designs that are tailored specifically for an application enables OPTOMAN to feel confident about their offerings for space communication field.

OPTOMAN offers a lineup of optics and coatings designed to tackle the specific challenges of laser space communication.

OPTOMAN’s laser optics are made with the resilience required to withstand the most extreme space environments. Rigorous testing has led to optics with extended lifetimes, minimising the need for frequent replacements and costly downtime, and strengthening the reliability of laser space communication systems. Coatings are custom-engineered to withstand those cosmic elements unique to space communications, so they can provide a protective shield against radiation, temperature fluctuations, and the vacuum of space, ensuring stability and unwavering functionality.

Custom coating designs can also be created and tailored to the specific requirements of the mission to enhance the reliability and performance of the optics, and ensure they are in perfect harmony with your objectives.

The cosmic arsenal: technology and measurements

In the quest for superior laser space communication, having access to relevant technology and measurements is crucial.

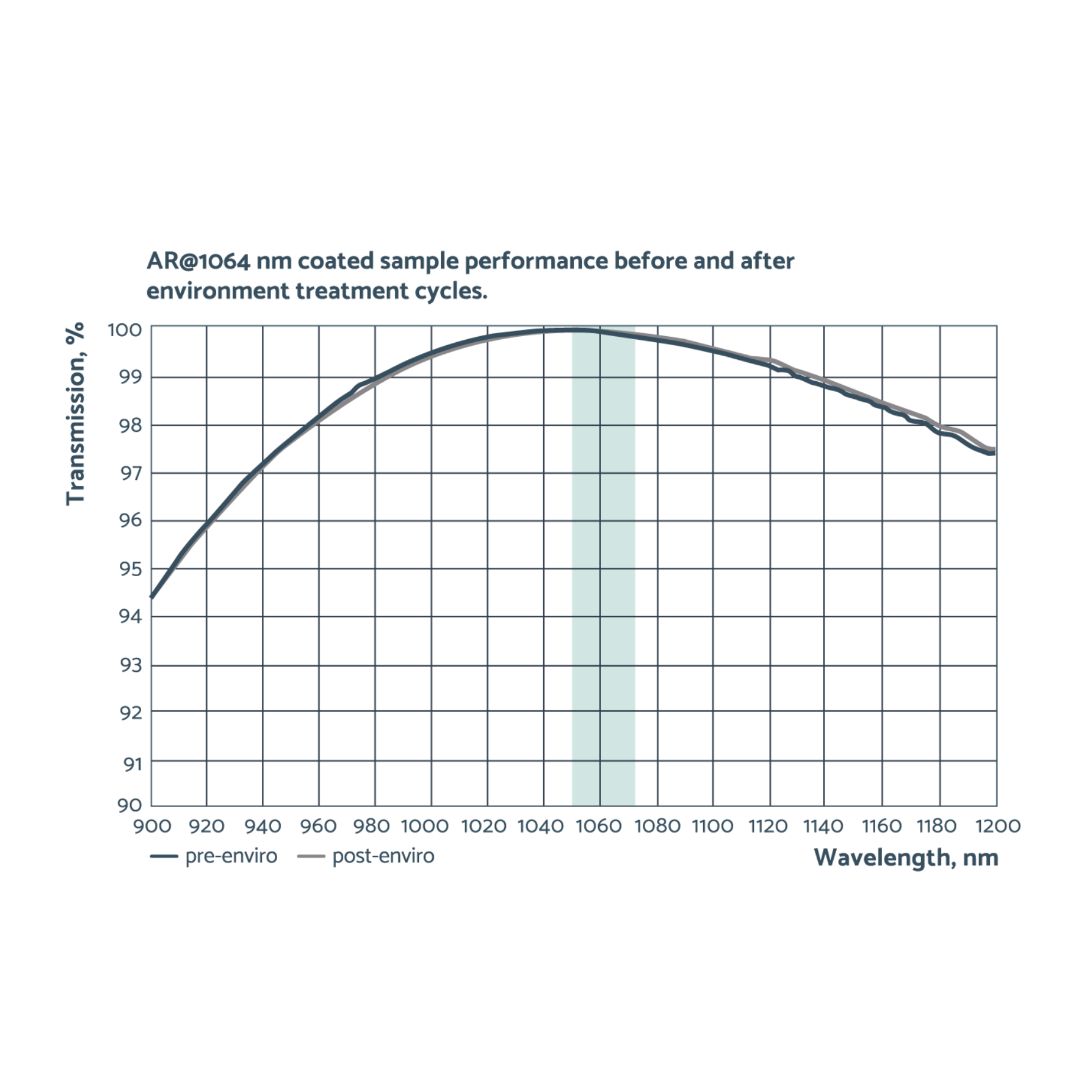

OPTOMAN’s arsenal of optical solutions is supported by comprehensive environmental stability and absorption measurements. These provide vital clues to understand how optics perform in the challenging conditions of space, equipping engineers with the knowledge needed to make informed decisions.

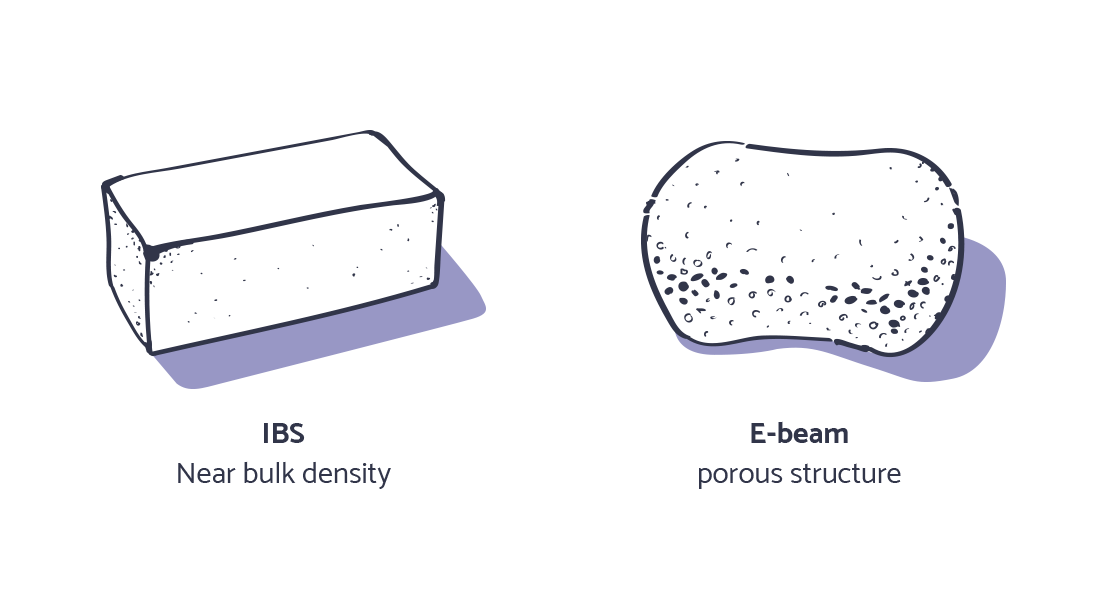

OPTOMAN’s IBS-coated components stand out for their exceptional durability and environmental stability, thanks to their high-density layers. These coatings are ideal for on-field applications. Here’s why:

- Exceptional spectral performance: OPTOMAN’s coatings can offer transmittance exceeding 99.98% for AR/AR coated components and reflectance of R>99.995% for high reflective coatings. Such spectral performance ensures minimal loss of laser power.

- High damage threshold: OPTOMAN’s coatings can withstand extremely powerful laser beams, with a threshold exceeding >426 kW/cm @ 1070nm, CW for HR coatings. This makes them suitable for high-power laser systems.

- Versatility: These coatings are applied to a variety of optical components, from basic round and rectangular windows to complex shapes like wedges and prisms. Optics are also customizable, with a spectral range from 200nm to 5000nm, various substrate materials, including metal substrates and a range of shapes and sizes.

- Application optimised coating designs: OPTOMAN has developed various laser optics for space communication applications at its most popular wavelengths: 1550nm, 935nm, 830nm and others. One popular coating design for data receiving and transmitting laser systems is dichroic mirrors that are able not only survive in space, but thrive.

Anything else?

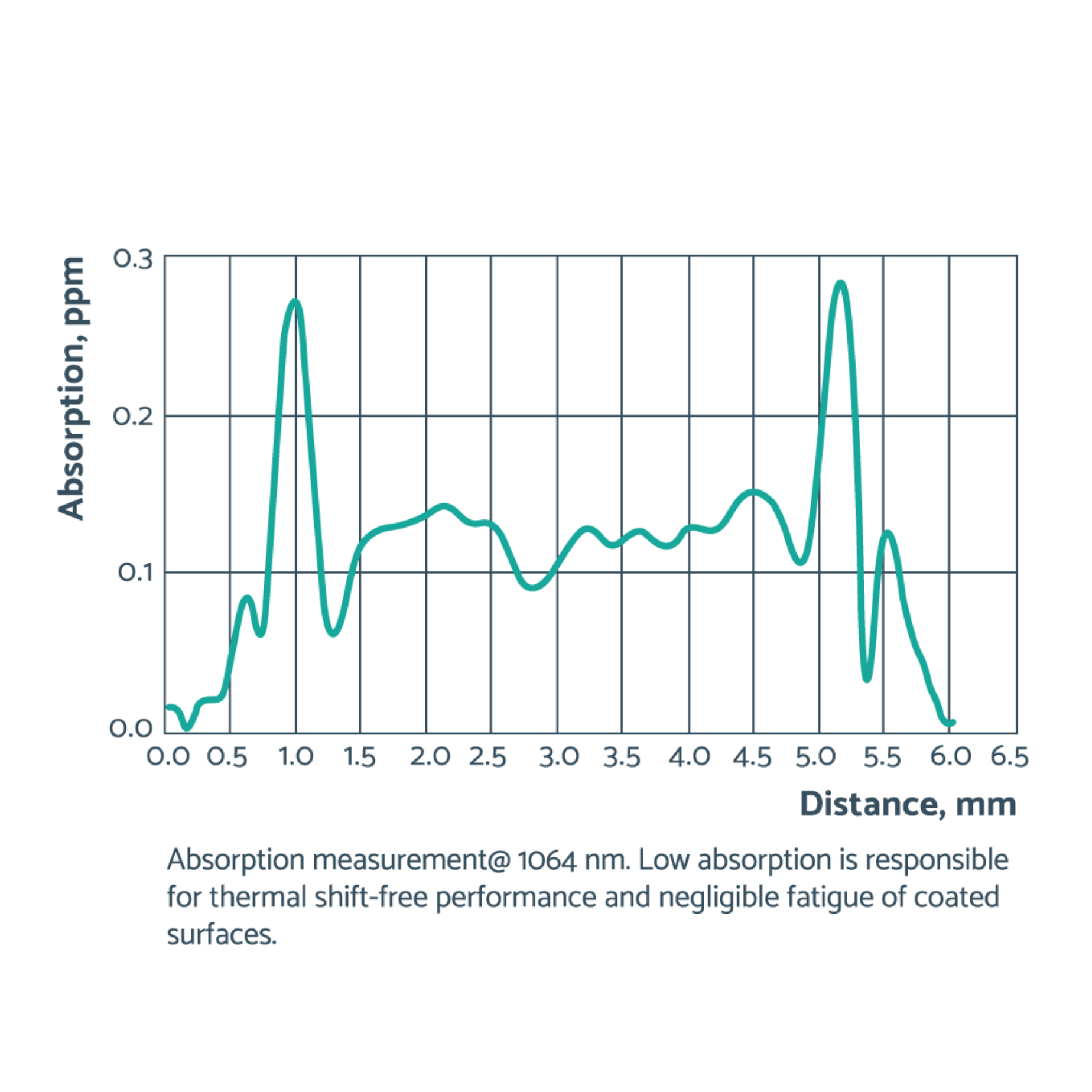

Key feature that ensures the longevity of optics is low absorption that reduces the laser damage risk and fatigue effect. OPTOMAN is able to reach absorption levels of 1ppm and less per coated surface. Transmitted wavefront distortion of <λ/20 @ 633nm per aperture, ensures high laser beam quality and stability which is crucial in guiding the laser beam in space when the data receiver is thousands of kilometers away. What’s more, OPTOMAN’s coatings maintain their performance independent of temperature and humidity, and they are highly durable.

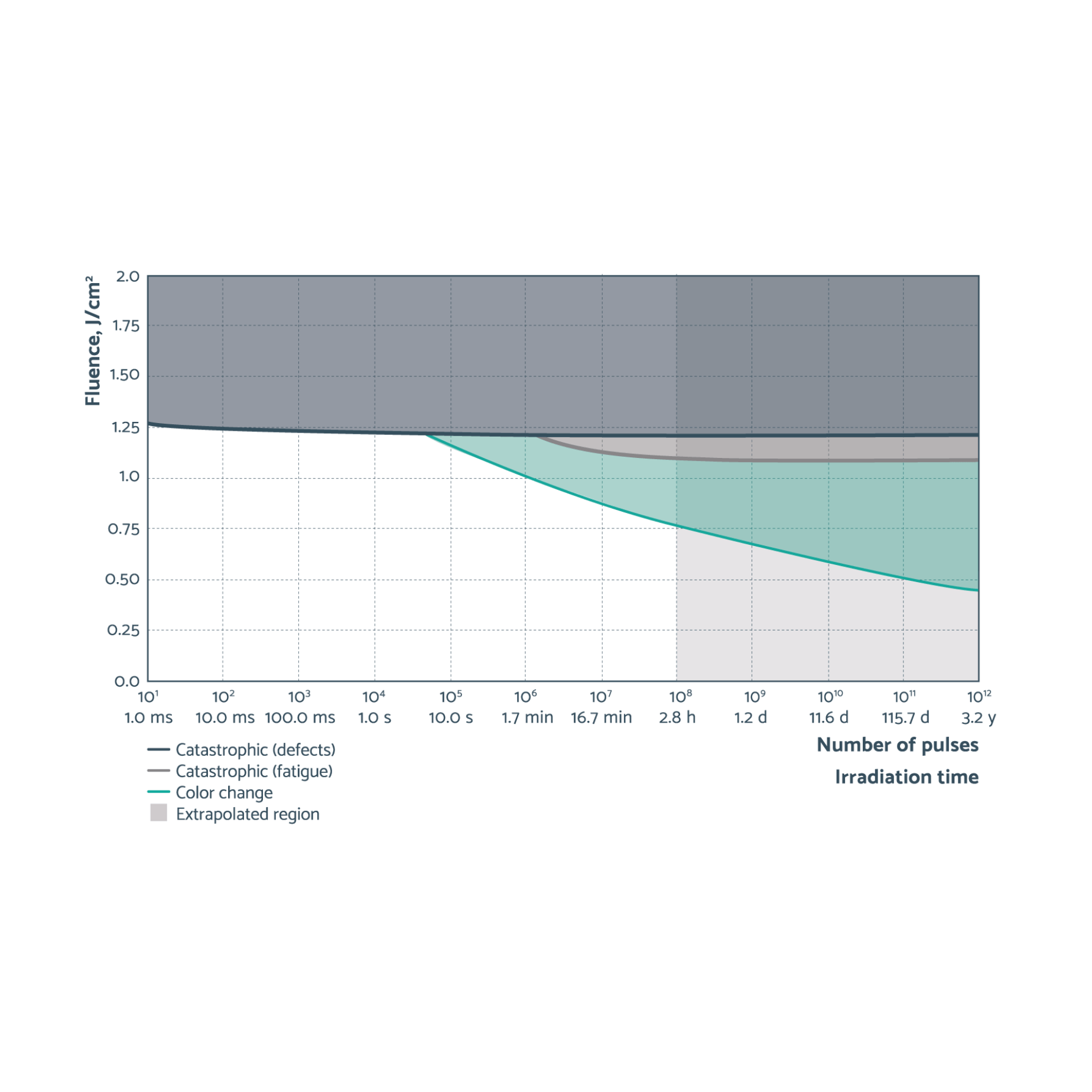

Retaining reliability: lifetime extrapolation

Measurement parameters:

Wavelength: 1030 nm

Pulse duration (FWHM): 500 fs

Repetition rate: 10 kHz

AOI: 45°

Polarization: Linear S

Beam diameter (1/e²): 185 µm

Catastrophic LIDT (108-on-1): 1.119 J/cm²

Color change LIDT (108-on-1): 0.78 J/cm²

The figure to the right demonstrates an ultrafast laser mirror lifetime measurement performed at the company Lidaris.