Whitepapers

Defining High Power in Laser Optics

High power in laser optics has no single definition, it depends on the application and pulse regime, with real limits set by Laser-Induced Damage Threshold (LIDT), not output power alone. Discover how OPTOMAN’s Ion Beam Sputtered (IBS) coatings push LIDT beyond 1 J/cm² at 200 fs, enabling reliable performance in ultrafast and high-power CW laser systems.

Sputtering vs Evaporation

Explore the differences between sputtering vs evaporation in optical coatings for enhanced film quality and performance.

IBS-Coated Optics for the Semiconductor Industry

OPTOMAN’s Ion Beam Sputtered (IBS) coatings redefine durability in semiconductor laser optics, maintaining stability and reflectance even after billions of pulses at deep-UV wavelengths. Designed for demanding environments from 193 nm to 1070 nm, these optics deliver longer lifetime and consistent performance in advanced semiconductor processing.

New Gen SuperHero Power IBS Waveplates

Introducing the SuperHero Power IBS Waveplates, engineered for ultrafast lasers with glue-free, zero-order, air-spaced design and <0.1% reflectance, to deliver femtosecond durability and unmatched polarization stability.

1550 nm Optics for Laser Communication

OPTOMAN’s IBS-coated optics enable high-speed, reliable laser communication for space and terrestrial networks. Designed for the 1550 nm telecom window, our laser mirrors, beam splitters, and dichroic mirrors ensure minimal absorption, low scattering, and long-term spectral stability. These space-grade components preserve signal strength, maintain polarization, and support mission-critical free-space optical links, overcoming the limitations of RF communication.

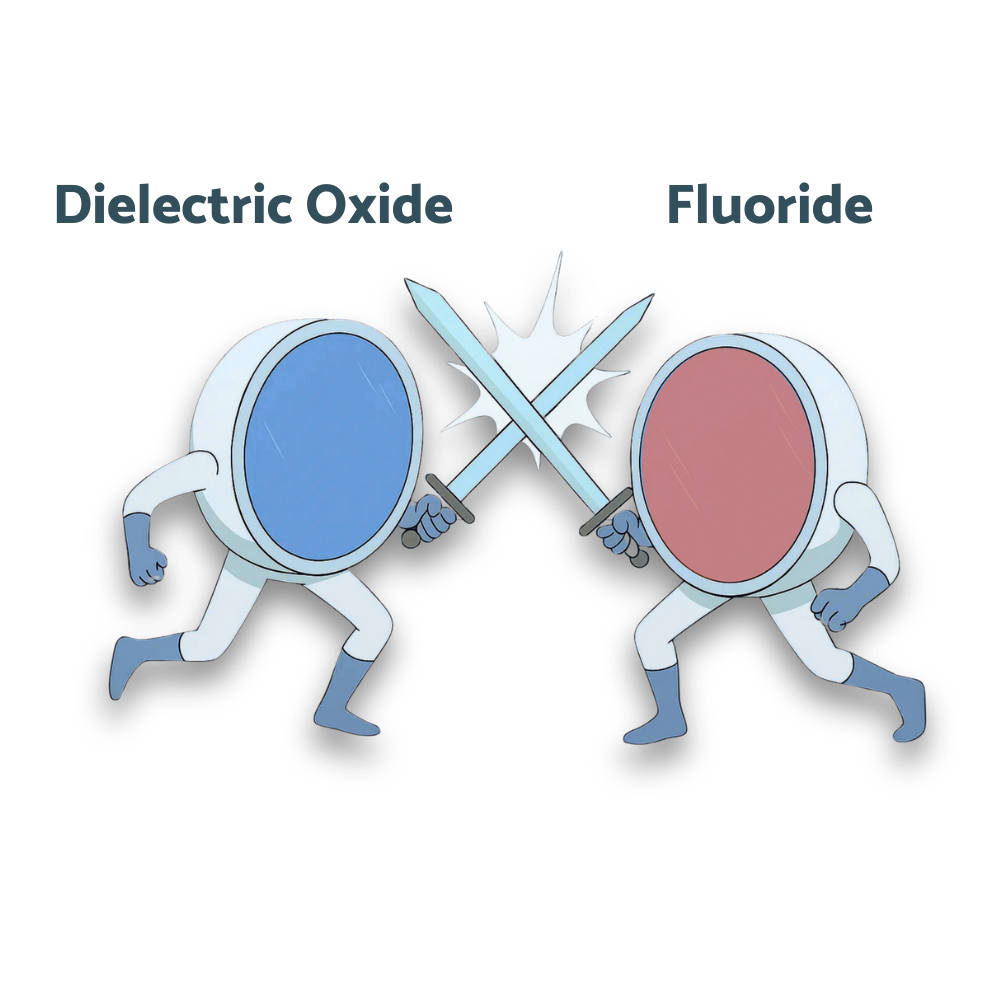

Dielectric Oxide vs Fluoride Deep-UV Coatings at 193 nm

This white paper explores advanced optical coatings for 193 nm ArF excimer lasers used in semiconductor lithography and micromachining. It compares fluoride-based and dielectric oxide coatings, highlighting how dielectric oxide coatings offer superior durability, low maintenance, and long-term stability in demanding deep UV (DUV) laser environments.

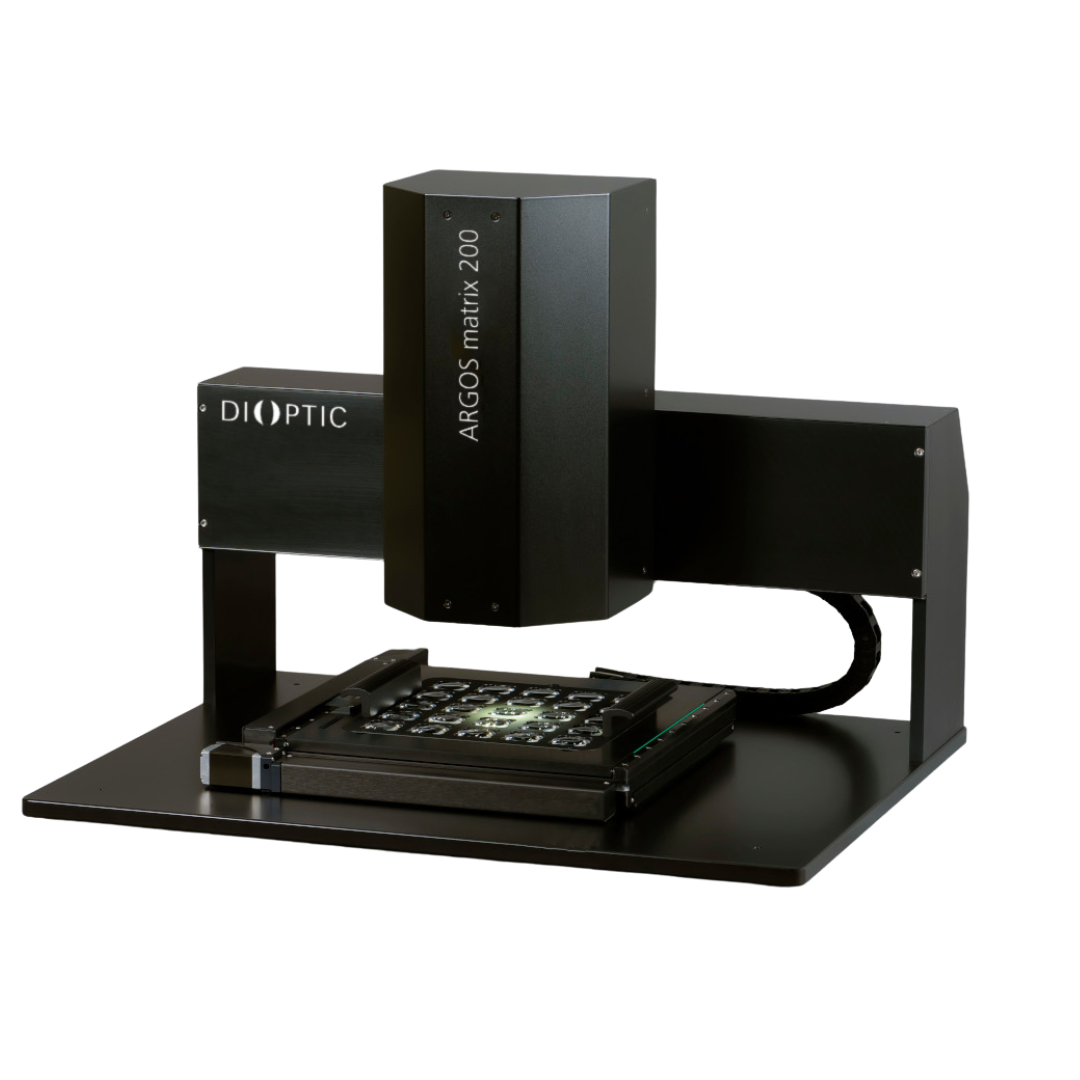

Surface Quality Control for Maximizing LIDT in High-Power Laser Optics

Surface defects like scratches, digs, or particles are a leading cause of premature laser-induced damage in high-power optical systems. In this whitepaper, OPTOMAN and DIOPTIC present how automated inspection with the ARGOS matrix and raster scan LIDT mapping can detect critical defects down to 1 µm. The findings show that even tiny absorption-inducing defects can reduce LIDT by over 40%. Learn how advanced metrology, defect mapping, and IBS coatings help minimize failure risk in optics for demanding applications like ICF and directed energy systems.

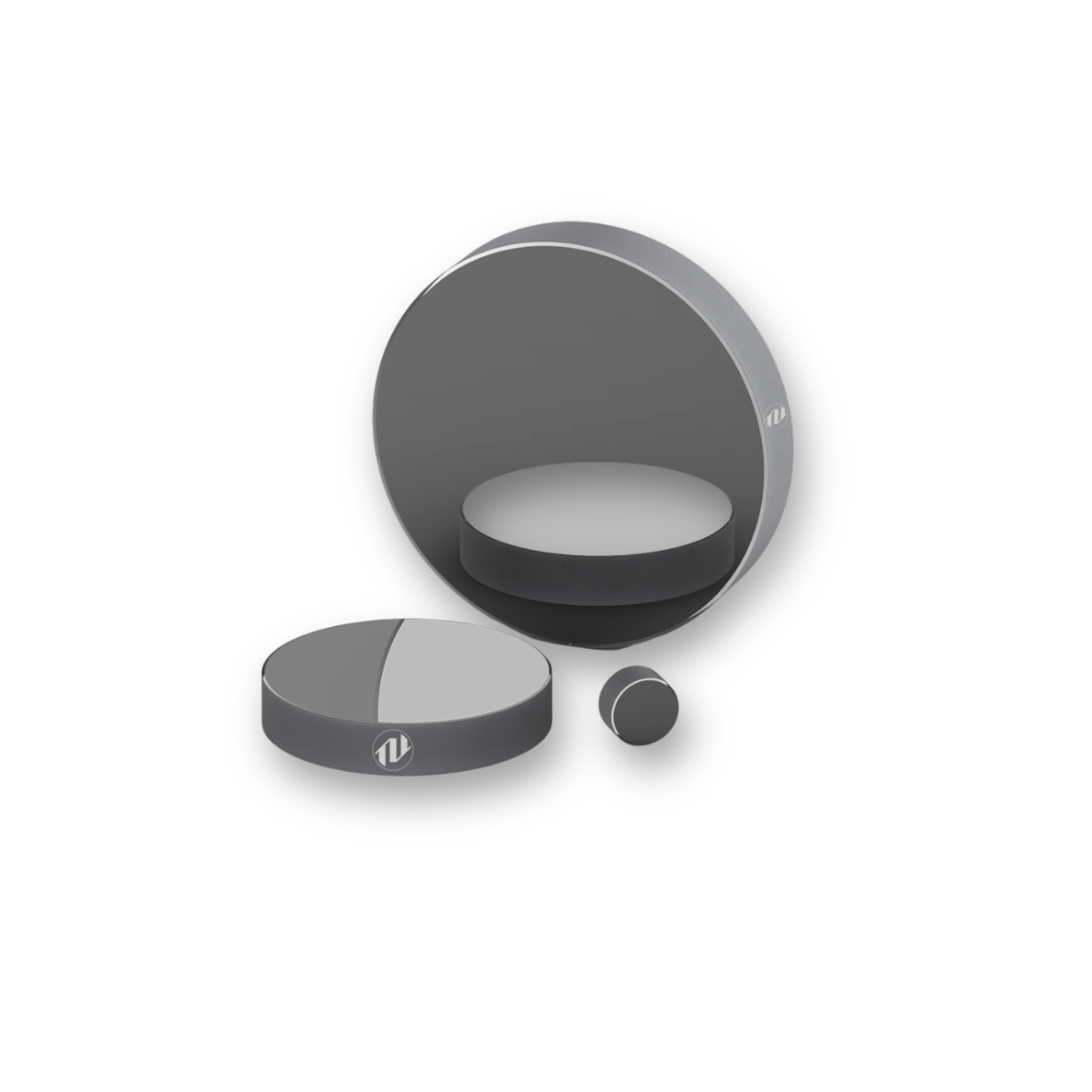

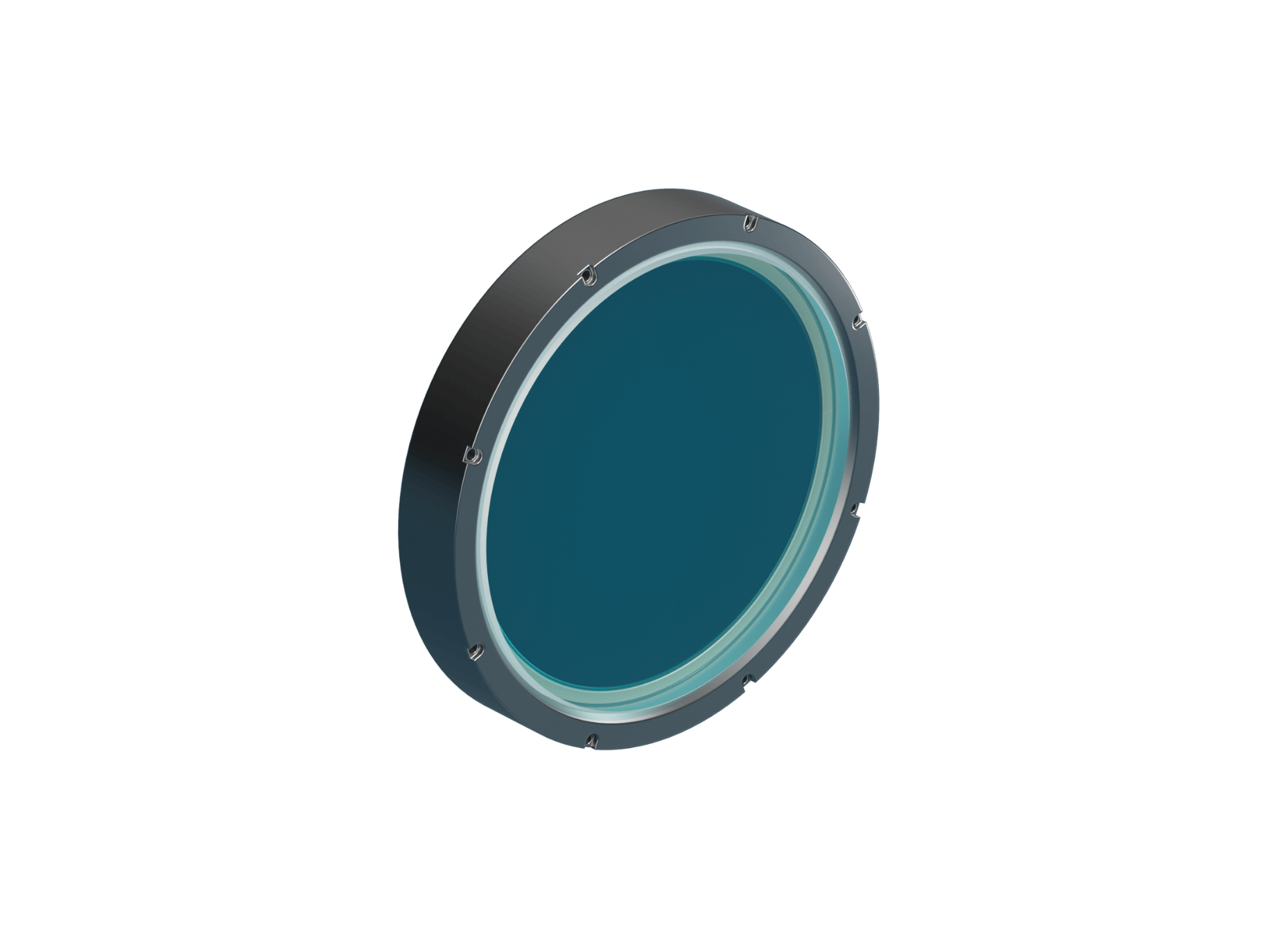

Large Diameter Optics

Large-diameter optics are essential components in some of the most advanced and demanding optical systems — from imaging systems in astronomical telescopes and ultrashort pulse compressors to inertial confinement fusion systems, large-scale interferometers, and directed energy laser weapons. This tech note covers the key factors to consider when choosing and using large optics in demanding laser setups.

IBS Coated Silicon Carbide Optics

Silicon carbide (SiC) is favored for laser mirrors in space and defense applications due to its light weight, high thermal conductivity, and mechanical robustness. Learn more about OPTOMAN IBS Coated SiC Mirrors in the following tech note.

Non-degrading ultrafast optics

Building on the success of Non-Degrading UV Optics, OPTOMAN introduces Non-Degrading Mirrors for Ti:Sa lasers and OPCPA laser systems, offering broadband coverage with no color change — ensuring uptime and reducing maintenance costs.

Non-Degrading UV Mirrors

It’s easy to assume that having the highest possible LIDT guarantees the suitability of laser optics for a high-power system. However, the UV part of the spectrum poses significant threats to laser optics, causing fatigue in the coating and leading to degradation and color change. OPTOMAN has a solution – learn more in this tech note.

Low Absorption Protective Windows

Low Absorption Protective Windows are widely used in laser processing to ensure high transmission of laser energy, protect laser system, and minimize thermal effects. Find out how OPTOMAN handles it in this tech note.