IBS-Coated Optics for the Semiconductor Industry

Semiconductors are the foundation of modern electronics, enabling ever smaller, faster, and more efficient devices. Achieving this progress relies on advanced photolithography and laser-based processing, where optics play a decisive role in determining throughput, efficiency, and costs.

For engineers working with ArF (193 nm), KrF (248 nm), XeCl (308 nm), other excimer, or even EUV laser systems, the challenges are well known: conventional coatings and substrates degrade under UV exposure, are susceptible to moisture, and only withstand a limited number of cleaning cycles. As highlighted in our whitepaper “Dielectric Oxide vs Fluoride Deep-UV Coatings at 193 nm”, fluoride coatings do provide excellent transparency at DUV wavelengths, but their sensitivity to moisture and dependence on tightly controlled environments severely limit their practicality. In real-world operation, such optics typically survive only a few cleaning cycles before performance begins to decline, directly impacting production efficiency through increased downtime and more frequent replacements.

Ion Beam Sputtering (IBS) redefines what optical coatings can achieve. By creating dielectric thin film layers with bulk-like density, ultra-low absorption, and virtually no defects, IBS delivers coatings that remain stable over humidity changes, temperature shifts, and mechanical wear. This stability translates into optics that perform reliably in semiconductor processing environments. Combined with UV-grade fused silica substrates, IBS-coated optics provide a durable, high-precision platform for photolithography, annealing, inspection, and advanced semiconductor processing.

Deep-UV Optics

Deep-UV wavelengths are essential in photolithography and other semiconductor laser processes, particularly with ArF excimer lasers (193 nm) and frequency-converted solid-state lasers (206/213 nm). Optics at these wavelengths face unique challenges: low damage thresholds, degradation from color-center formation, and limited lifetime when using fluoride-based coatings.

OPTOMAN’s IBS-coated DUV optics address these limitations. By combining oxide-based IBS coatings with high-purity substrates, they maintain reflectance and resist degradation even after billions of pulses. The following comparison highlights the difference in reflectance performance between conventional E-Beam sputtered fluoride coatings and OPTOMAN’s IBS oxide coatings at 193 nm.

Comparison of 193 nm of E-beam sputtered fluoride coating and IBS oxide coating reflectance spectrum measurements.

Precise characterization of 193 nm wavelength is challenging due to the limitations of standard spectrometers.

OPTOMAN employs “PhotonRT” by EssentOptics, a high-accuracy instrument tailored for deep-UV spectral evaluation. This ensures reliable and consistent validation of coating performance across production.

Lifetime tests performed on OPTOMAN IBS DUV mirrors at ~100 mJ/cm² fluence, 193 nm, for ~5 billion pulses demonstrated a normalized reflectance drop of less than 0.5%. This confirms exceptional stability in long-term semiconductor laser operation. For comparison, conventional fluoride-based coatings subjected to similar test conditions typically show reflectance degradation in the range of several percent, often failing within a fraction of the tested pulse count. This result translates directly to semiconductor applications: IBS-coated DUV mirrors extend service intervals, reduce the frequency of component replacement, and ensure consistent optical performance over billions of pulses.

High-Performance Sapphire Windows for 308 nm Excimer Laser Applications

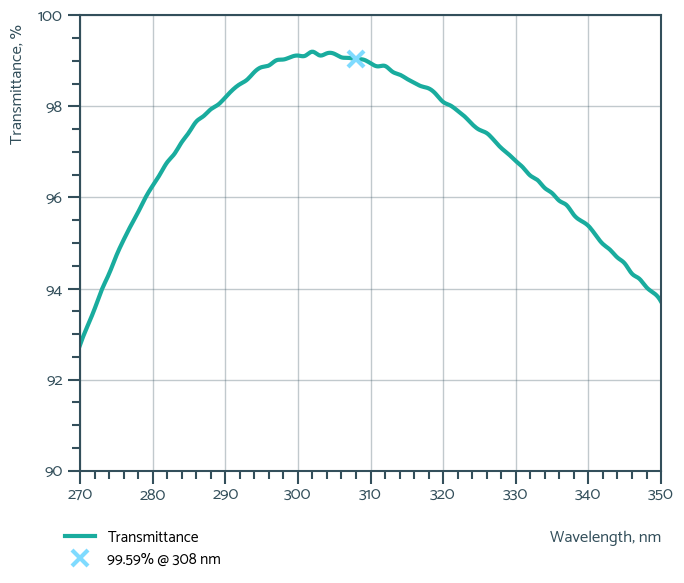

OPTOMAN’s 308 nm sapphire windows, coated with precision IBS AR layers, deliver high transmission, UV degradation resistance, and exceptional cleaning durability. Unlike standard optics that fail after a few maintenance cycles, these windows preserve performance over time, reducing replacements, minimizing downtime, and ensuring reliable operation in demanding excimer laser applications such as LTPS annealing, laser lift-off, and layer transfer.

UV-grade sapphire window design example:

Substrate material: UV-grade sapphire

Diameter: 60.0 mm +0/-0.1 mm

Thickness: 5.0 mm +/-0.1 mm

Wedge, S1: <10 arcsec

Clear aperture: >85%

Surface Quality, S1/S2: MIL 20/10 S/D

Transmitted WFD: λ/6 PV @633nm

Protective chamfers: 0.4 ±0.1 mm at 45°

Chips: <0.2 mm stoned

Coatings (IBS):

S1: AR≤0.2% @308nm; AOI=0°;

Overall transmittance >98.5%*

S2: AR≤0.2% @308nm; AOI=0°*;

* AR≤0.1% @308nm; AOI=0° available upon request

Suitable optics: IBS-coated sapphire windows optimized for 308 nm operation.

Standard Wavelengths: (1030 nm, 515 nm, 343 nm)

1030 nm, 515 nm, and 343 nm optics are OPTOMAN’s bread and butter – proven, high-volume solutions already trusted across the semiconductor market. Available with award-winning Non-Degrading IBS coatings, they deliver stable long-term performance and extended lifetime, helping laser system builders reduce maintenance, improve uptime, and lower total cost of ownership.

Non-Degrading in stock options

Standard wavelengths in stock options

Waveplates for Semiconductor Applications

Polarization control is critical in many semiconductor processes, from lithography to wafer inspection. OPTOMAN’s New Generation SuperHero Power IBS waveplates offer exceptional LIDT, premium retardance tolerance, with Zero-order Air-spaced design ensuring precision and long-term stability. A very attractive option for polarization management in semiconductor laser systems.

Process Chamber Windows

OPTOMAN supplies ready-to-install IBS-coated process chamber window assemblies, reducing BOM, assembly complexity and integration time for OEMs and tool builders. With <3 ppm absorption and proven resilience to >426 kW/cm² at 1070 nm CW, these assemblies ensure long lifetime, stability, and reliability in semiconductor laser processing and other applications where uptime and precision are critical.

Design example

Dual-Band Anti-Reflection Coating

Conclusion

As semiconductor systems advance toward higher power, tighter tolerances, and longer expected service intervals, optics often define the limits of performance and uptime. Conventional coatings and substrates cannot reliably meet these demands, especially under the harsh UV and high-duty-cycle environments of modern fabs and tool builders. OPTOMAN’s IBS-coated optics address this challenge head-on, delivering quantifiable improvements in lifetime, stability, and resistance to degradation across critical wavelengths from 193 nm to 1070 nm.

From ArF DUV mirrors that maintain reflectance after billions of pulses, to 308 nm sapphire windows that withstand repeated cleaning without performance loss, to non-degrading optics at 1030/515/343 nm, new-generation waveplates, and ready-to-install chamber window assemblies, OPTOMAN provides a full spectrum of optics designed for reliability in semiconductor applications. The result is lower replacement frequency, minimized downtime, and reduced total cost of ownership — optics engineered to keep semiconductor tools running at their highest potential.

Contact us for application-optimized laser optics engineered specifically to your needs.