New Gen SuperHero Power IBS Waveplates

Customer-Driven Innovation in Ultrafast Optics

A leading laser micromachining systems manufacturer faced a recurring issue: waveplates in their laser systems were degrading too quickly, undermining the long-term stability of polarization control in ultrafast laser beam paths. Their requirement was clear – all optical components must last at least five years to ensure the machine’s reliability.

OPTOMAN responded by investing in targeted R&D to develop a new generation of IBS-coated waveplates designed specifically for high-duty-cycle ultrafast applications. These waveplates deliver:

- Femtosecond durability, verified at 300 kHz rep rates

- Glue-free mechanical mounting, eliminating stress and outgassing issues

- IBS anti-reflective coatings with <0.1% reflectance, ensuring maximum efficiency

The result is a waveplate platform that sets a new durability benchmark in the field and directly addresses customer demand for long-lasting, maintenance-free optics.

OPTOMAN introduces new generation IBS Coated Waveplates – built to survive the extremes of ultrafast lasers.

Waveplates are essential optical components for controlling polarization. By introducing a precise phase shift between orthogonal polarization components, they enable critical functions such as converting linear to circular polarization, rotating the polarization axis, or fine-tuning polarization for high-precision laser setups.

They play a key role in ultrafast and high-power laser systems, including:

- Beam steering and attenuation through polarization rotation.

- Frequency conversion stages (SHG, THG, OPA/OPCPA).

- Pulse compression and amplification, where polarization stability is vital.

- Scientific, medical, and defense laser applications that demand reliable polarization control.

Zero-order waveplates achieve retardance (quarter-wave or half-wave) with a very thin birefringent plate. Because of this, they are far less sensitive to wavelength or temperature fluctuations compared to multiple-order designs, making them the top choice when precision and stability matter most.

Air-spaced waveplates use two thin plates separated by a narrow air gap, aligned to produce the desired retardance. With no adhesives or bonding layers, they withstand higher laser powers, resist UV-induced degradation, and deliver long-term performance under demanding conditions.

OPTOMAN’s IBS Waveplates combine these design advantages with outstanding performance, making them ideal for material processing and other high-energy applications:

- Exceptional damage threshold – > 1 J/cm² @ 1030 nm, 200 fs for Yb:YAG laser wavelengths (1030, 515 nm).

- Premium retardance tolerance of λ/300, ensuring reliable performance in the most sensitive polarization control tasks.

- Zero-order design – broad bandwidth, greater than ±1% wavelength deviation tolerance, and minimal sensitivity to temperature variations.

- Air-spaced construction – eliminates adhesives, ensuring higher LIDT, long-term stability, and resistance to degradation.

The result: precise, stable, and long-lasting polarization control, even under the toughest laser conditions.

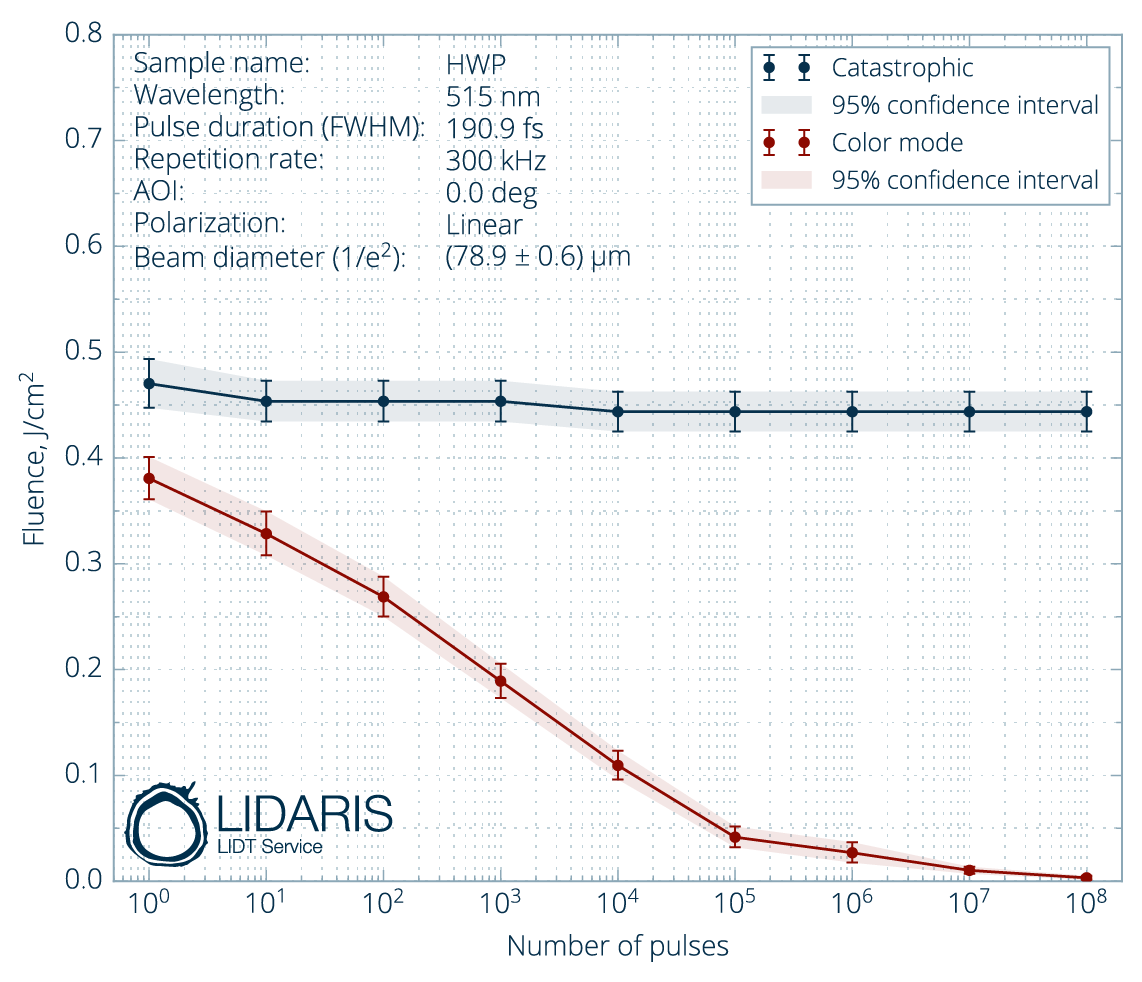

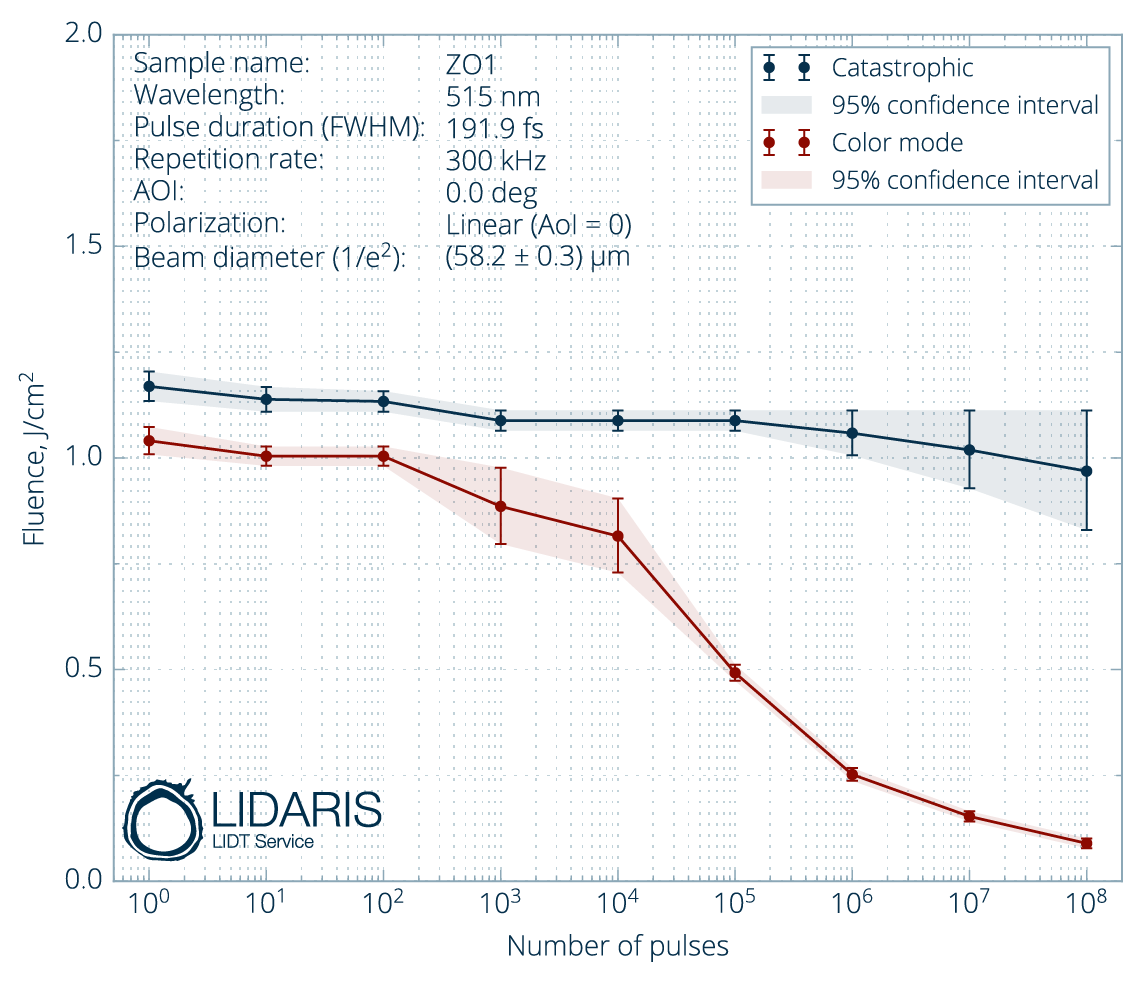

LIDT comparison of OPTOMAN’s Waveplates @ 515 nm

| Standard

R < 0.2% @ 515 nm Catastrophic LIDT (Measured): >0.44 J/cm², 515 nm, 200 fs, 300 kHz

|

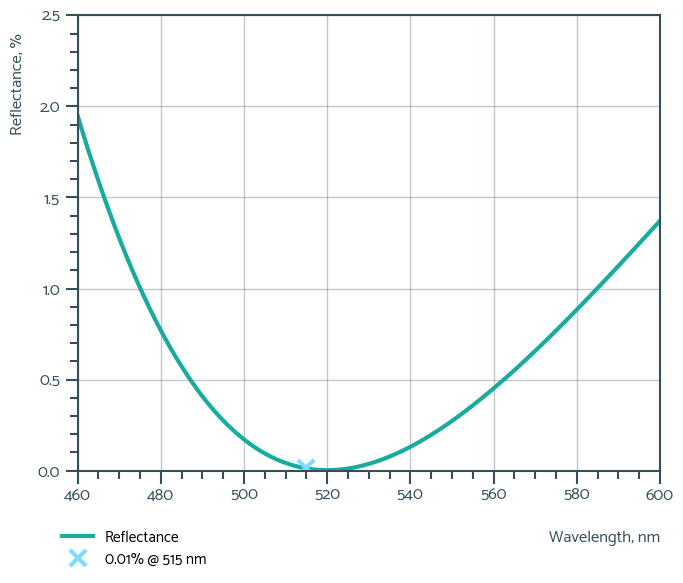

SuperHero Power

R < 0.1% @ 515 nm Catastrophic LIDT (Measured): >0.97 J/cm², 515 nm, 200 fs, 300 kHz

|

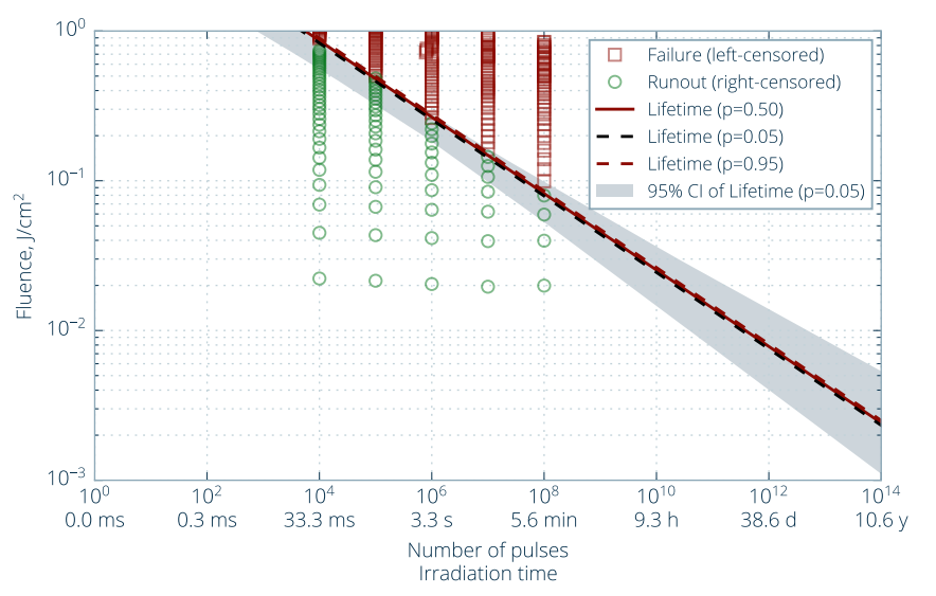

Lifetime extrapolation for Color mode damages.

This leap in damage resistance means extended operational lifetimes, lower total cost of ownership, and confidence that your system won’t fail when pushed to the limit.

ZERO-ORDER AIR-SPACED WAVEPLATES

HWP-AS-ZO-1030-20.0-AR1147-AR1147 and QWP-AS-ZO-1030-20.0-AR1147-AR1147

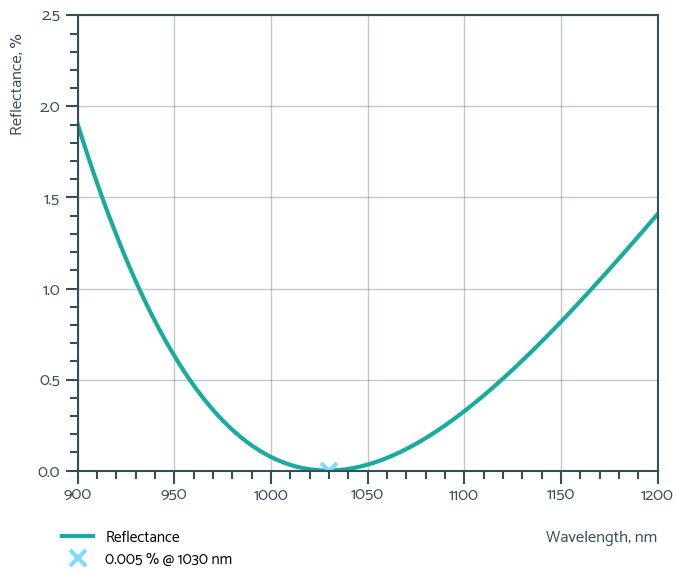

| Anti-reflective surface: R < 0.1% per surface @ 1030 nm, AOI = 0°

Zero-order: minimal sensitivity to temperature variations. Air-spaced: ensuring higher LIDT, long-term stability, and resistance to UV-induced degradation. LIDT (Estimated): >1.92 J/cm², 1030 nm, 200 fs, 300 kHz |

|

Environmental Stability: Coating design suitable for environmental changes, thermal cycling, and mechanical wear.

Available in both quarter-wave and half-wave designs.

ZERO-ORDER AIR-SPACED WAVEPLATES

QWP-AS-ZO-515-20.0-AR1018-AR1018 and HWP-AS-ZO-515-20.0-AR1018-AR1018

| Anti-reflective surface: R < 0.1% per surface @ 515 nm, AOI = 0°

Zero-order: minimal sensitivity to temperature variations. Air-spaced: ensuring higher LIDT, long-term stability, and resistance to UV-induced degradation. LIDT (Measured): >0.97 J/cm², 515 nm, 200 fs, 300 kHz |

|

Environmental Stability: Coating design suitable for environmental changes, thermal cycling, and mechanical wear

Available in both quarter-wave and half-wave designs.