Sputtering vs Evaporation

In the field of advanced optical coatings, the choice of deposition technology directly influences film quality, reproducibility, and performance under demanding conditions. Among the leading Sputtering and Evaporation methods are Ion Beam Sputtering (IBS), Magnetron Sputtering, Ion Beam Assisted Deposition (IAD), and Electron Beam (E-Beam) evaporation. While all are used for producing thin films across a variety of optical applications, their operational principles, film characteristics, and suitability for individual cases diverge significantly. Each method presents a unique balance of precision, scalability, and cost, which must be carefully considered when targeting specific optical performance. Understanding these distinctions is essential for selecting the most appropriate technology for both R&D and high-volume manufacturing environments.

Through focused process development and high-throughput coating runs, OPTOMAN has significantly reduced the cost drivers of IBS, making it highly competitive even for serial production, not just R&D.

Ion Beam Sputtering (IBS)

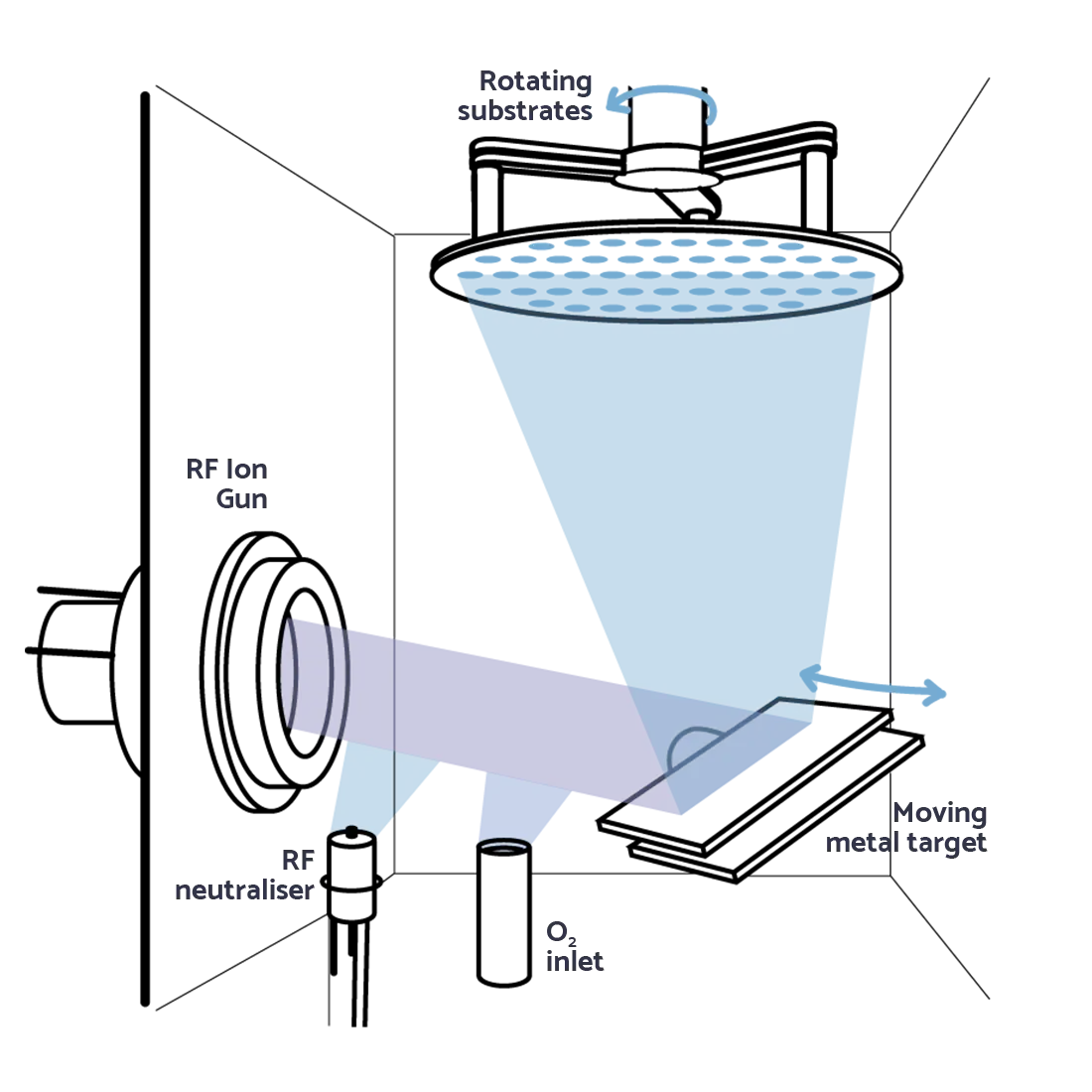

Ion Beam Sputtering is a high-precision physical vapor deposition technique in which a focused, monoenergetic beam of inert ions, typically argon, is directed at a target material within a high-vacuum chamber. The ion bombardment ejects atoms from the target surface, which then travel in a well-collimated path and condense onto rotating substrates to form a thin film. This configuration allows for independent control of ion energy, beam angle, and flux, enabling the deposition of dense, low-defect coatings with exceptional uniformity and surface quality.

Key benefits of IBS coatings:

- Cutting-edge spectral requirements and repeatability

- High resistance to laser irradiation

- Virtually no scattering

- Very low absorption losses

- Bulk-like packing density

- Excellent thermal and mechanical stability

Ion Beam Sputtering System Schematic

Because the ion beam is monoenergetic (ions have equal energy) and highly collimated, it enables extremely precise thickness control and the deposition of very dense, high-quality films compared to Magnetron Sputtering. Its ability to produce highly stable, low-loss coatings makes it the preferred technology for demanding laser applications.

OPTOMAN IBS machines have relatively high deposition rates and produce large-area (~500mm) coatings with superior uniformity (<0.5% across the area).

Although IBS is not perfect. Because the sputter yield is limited by the narrow, well‑defined ion beam, IBS typically exhibits lower deposition rates compared to magnetron sputtering, which trades off precision for throughput. It also has high compressive coating stress (~500 MPa) (however, initial substrate flatness may be maintained by process optimisation or additional manufacturing steps).

OPTOMAN production and R&D team, having extensive knowledge about IBS machines, was able to mitigate most of the disadvantages of IBS, busting the myth that IBS is not competitive in serial production cases. OPTOMAN IBS machines have relatively high deposition rates and produce large-area (~500mm) coatings with superior uniformity (<0.5% across the area).

Magnetron Sputtering

Magnetron Sputtering is a plasma-assisted physical vapor deposition technique in which a target material is bombarded by energetic ions generated in an inert argon atmosphere. A strong negative voltage is applied to the target material, attracting positively charged Ar⁺ ions from the plasma. These ions strike the target surface, ejecting atoms through momentum transfer, which then travel through the vacuum chamber and condense onto the substrate to form a thin film.

Key benefits of producing MS coatings:

- High deposition rates

- Great scalability for large-area substrates

- Cost-effective volume production

- Broad material compatibility

- Moderate absorption and LIDT performance

Magnetron Sputtering System Schematic

While magnetron sputtering enables higher deposition rates and is widely used in industry, it offers less control over ion energy and directionality, which impacts film density and optical performance in multilayer coatings. Its films are generally more susceptible to degradation under high-fluence or high-repetition-rate conditions.

Electron Beam (E-Beam) Evaporation

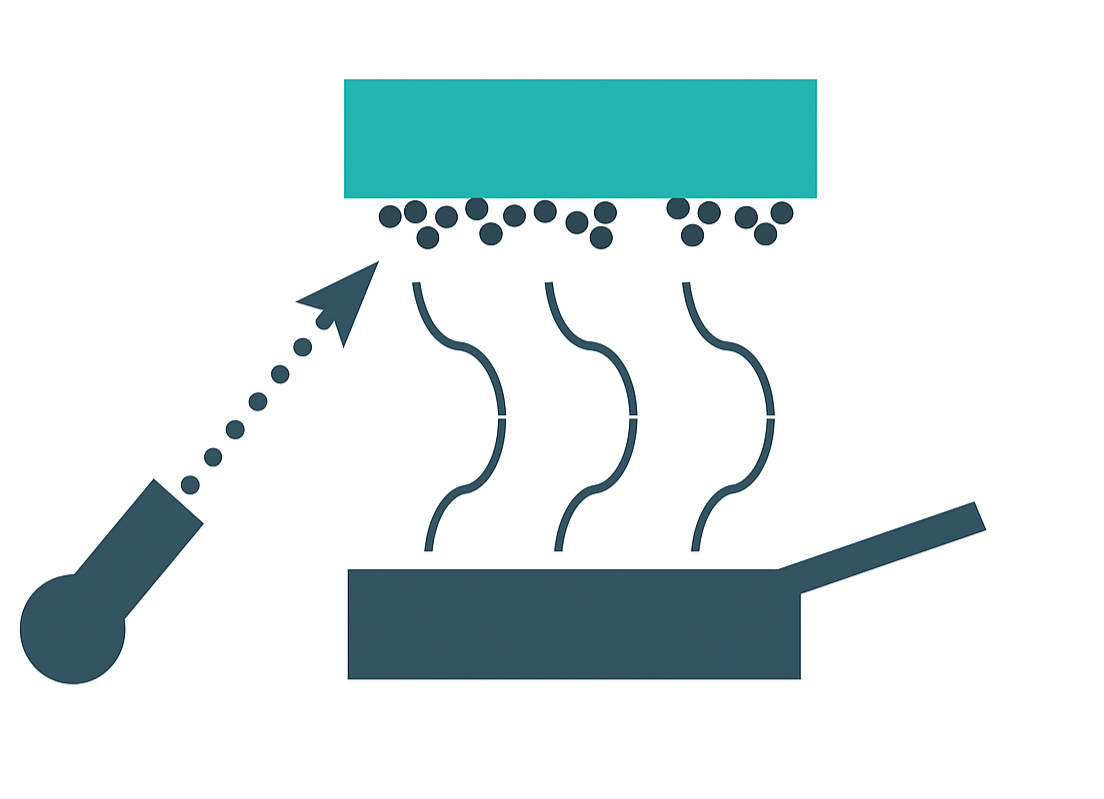

Electron beam evaporation is a thermal evaporation technique in which an intense, focused beam of high-energy electrons is directed at a solid source material under high vacuum. The electron beam rapidly heats the target, causing it to evaporate and form a vapor cloud that condenses onto the substrate to form a thin film. The electron beam is typically bent using magnetic fields to prevent direct exposure of the hot filament to the evaporated material, ensuring system stability.

Key benefits of E-Beam evaporation coatings:

- High deposition rates

- Cost-effective for large-area, non-critical coatings

- Capable of evaporating high-melting-point materials

- Simple system architecture and widespread availability

- Compatible with ion-assist enhancements (e.g., IAD)

- Suitable for broadband AR or decorative applications where ultra-low loss is not required

Electron Beam Evaporation System Schematic

E-Beam can deposit a wide range of materials, including high-melting-point oxides, and is often used in conjunction with ion-assisted processes like IAD to improve film quality. However, in its basic form, E-Beam evaporation tends to produce porous, columnar-structured films with low packing density and limited environmental durability, making it less suitable for high-power or precision laser applications. Its key advantages lie in its simplicity, cost-efficiency, and high deposition rates.

Ion Beam Assisted Deposition (IAD)

Ion Beam Assisted Deposition (IAD), also known as Ion Beam Enhanced Deposition (IBED), combines conventional vacuum deposition techniques, such as thermal evaporation or electron beam evaporation, with a directed low-energy ion beam aimed at the substrate during film growth. The ion bombardment delivers additional energy to the growing film, promoting surface migration, reducing void formation, and improving film density, adhesion, and structural stability.

Key benefits of IAD coatings:

- Improved film density compared to purely evaporative methods

- Enhanced adhesion through ion mixing at the substrate interface

- Partial control of film stress and morphology

- Higher deposition rates than IBS

- Flexible integration with existing evaporation platforms

- Suitable for moderately demanding optical applications

Ion Beam Assisted Deposition System Schematic

Unlike IBS, where the ion beam is the primary source of sputtered material, IAD uses the ion beam solely to modify the film during or after material arrival. This makes IAD more flexible in material choice and relatively higher in deposition rate than IBS, while still offering partial control over microstructure and film quality. However, because the ion and material fluxes are not independently controlled, process precision is lower compared to IBS. As a result, IAD coatings tend to be less dense, less durable, and less environmentally stable, with reduced reflectivity and limited reproducibility in high-performance optics applications.

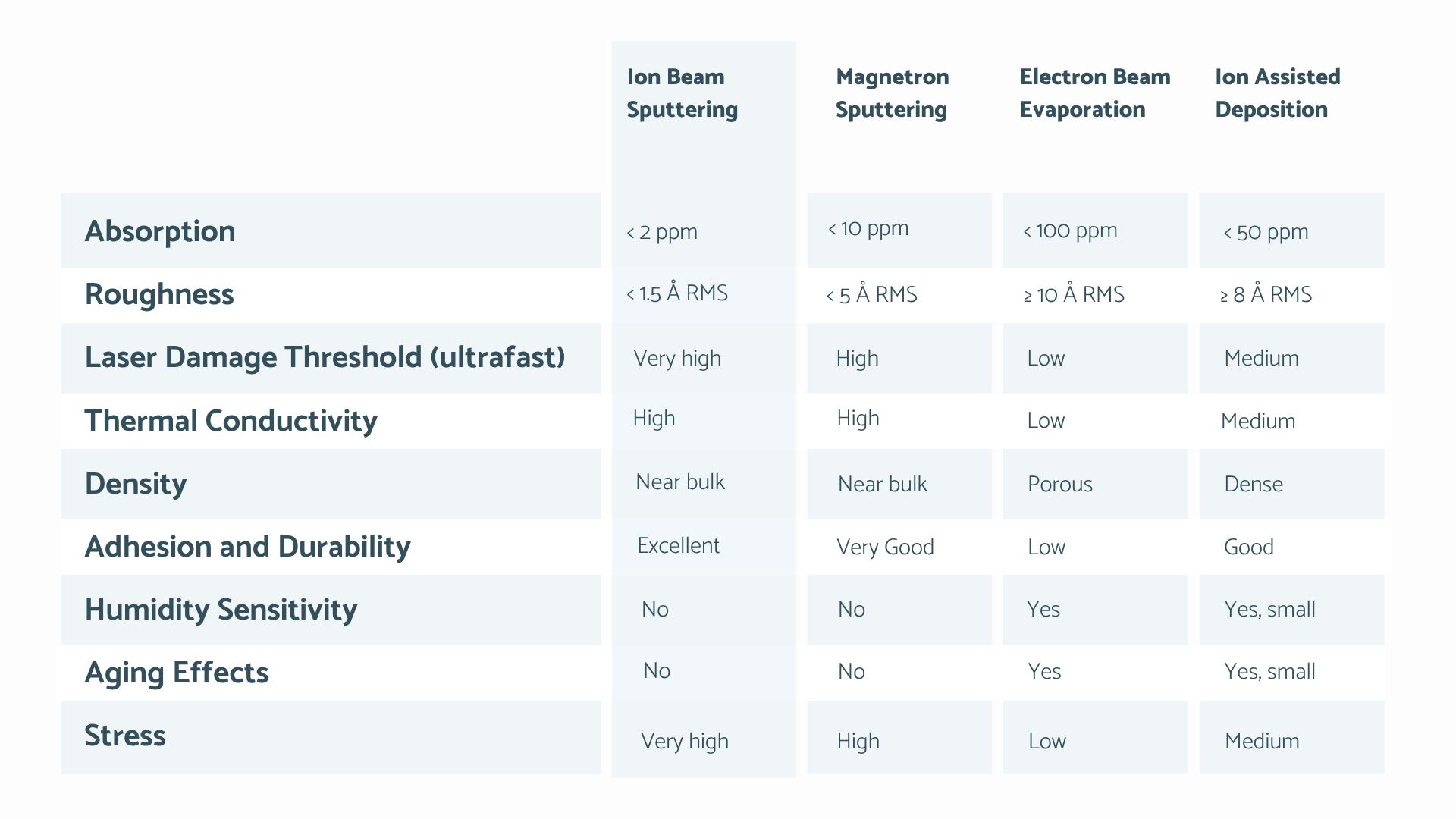

Comparison of Thin-Film Properties

When selecting a deposition technology for optical coatings, critical film properties such as density, absorption, surface roughness, and laser-induced damage threshold (LIDT) play a decisive role in determining performance. IBS continues to set the benchmark, producing coatings with bulk-like density, superior surface quality, ultra-low absorption, and minimal scatter, all essential attributes for high-performance optical systems operating in ultrafast and high-power laser regimes. The independent control over ion parameters in IBS enables unmatched layer precision and consistency, resulting in coatings that excel in both spectral fidelity and environmental stability.

Magnetron sputtering, IAD, and E-Beam evaporation represent varying trade-offs between throughput, process control, and coating quality. Magnetron sputtering offers higher deposition rates and scalability, but typically yields columnar microstructures with higher roughness and absorption. IAD improves upon E-Beam by enhancing film density and adhesion via directed ion bombardment during growth. However, it still lacks the precision of IBS and is sensitive to parameter fluctuations. E-Beam evaporation, while cost-effective and simple, generally produces the least dense and most environmentally sensitive films.

Ultimately, each method has its place, but for precision optics with stringent laser and environmental requirements, IBS remains the most robust solution.

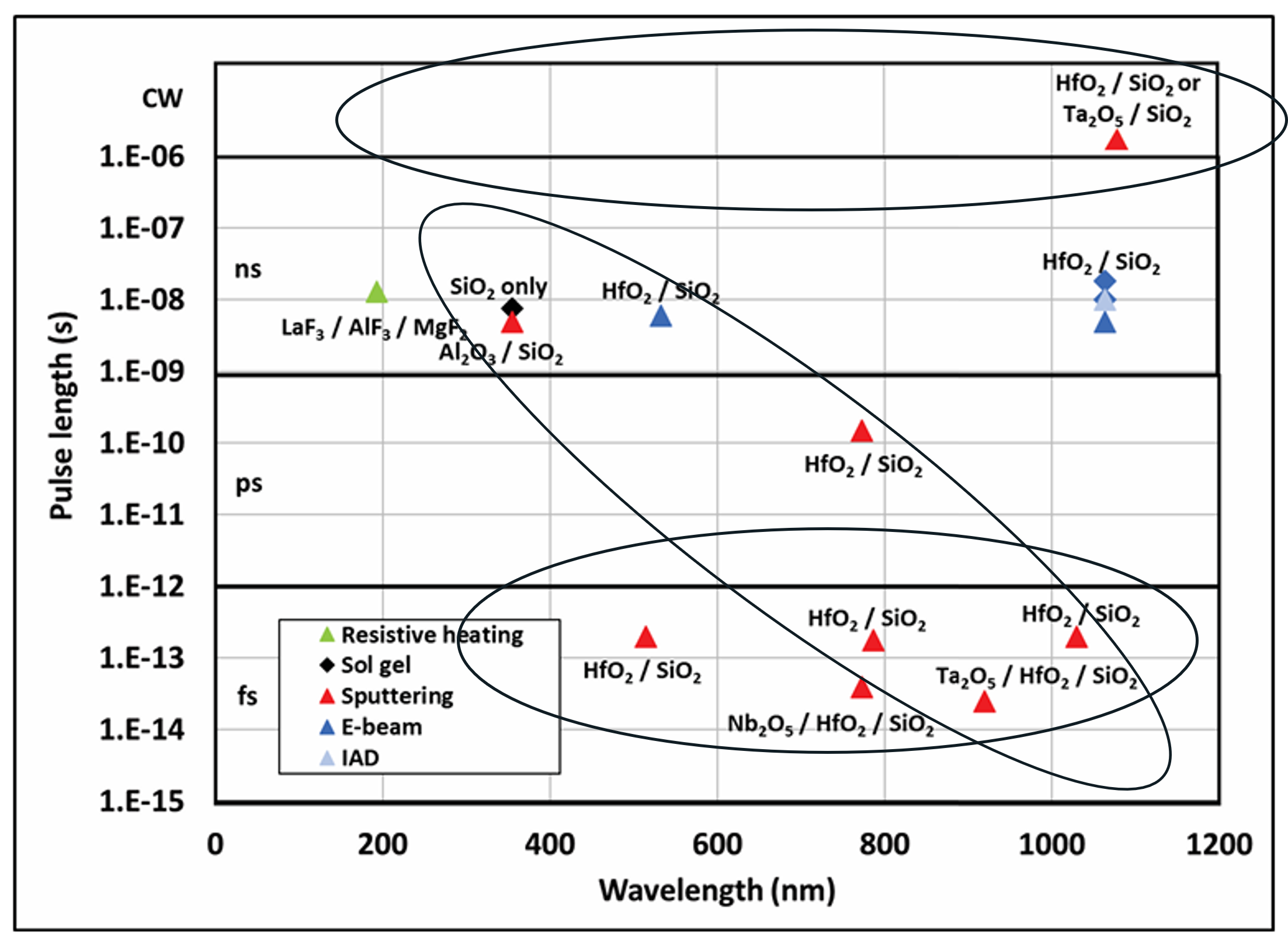

LIDT performance is one of the most critical factors in high-power laser optics. Coatings produced by IBS (noted as “sputtering” in the chart below) consistently outperform other technologies, especially in the ultrafast (fs) regime. The chart further illustrates the strong correlation between coating method, material selection (e.g., HfO₂/SiO₂), and achievable damage resistance, reinforcing IBS as the deposition method of choice for high-power and short-pulse laser optics.

Christopher J. Stolz, Raluca A. Negres, “Ten-year summary of the Boulder Damage Symposium annual thin film laser damage competition,” Opt. Eng. 57(12) 121910 (18 December 2018) https://doi.org/10.1117/1.OE.57.12.121910

Why Our Main Focus is on IBS

At OPTOMAN, meeting the highest optical performance standards is not negotiable. IBS was chosen exclusively for its ability to deliver dense, ultra-smooth, and defect-free coatings that maintain spectral stability and optical integrity even under extreme laser and environmental conditions.

By exclusively employing IBS technology, OPTOMAN ensures that every coating delivers industry-leading spectral performance, laser resistance, and long-term reliability. Through continuous refinement, OPTOMAN has pushed IBS beyond traditional limitations and significantly reduced the cost drivers of IBS, meeting the needs of both cutting-edge R&D and volume production. Whether producing mirrors for femtosecond laser pulses, dichroic filters, or Non-degrading UV coatings, IBS is guaranteed to meet your standards without compromise.