Large Diameter Optics

Large-diameter optics are essential components in some of the most advanced and demanding optical systems — from imaging systems in astronomical telescopes and ultrashort pulse compressors to inertial confinement fusion systems, large-scale interferometers, and directed energy laser weapons. In all of these applications, high quality is critical to ensure performance, precision, and reliability.

THE CHALLENGE

As optical components increase in size, so do the challenges involved in producing them. For example, maintaining coating uniformity across large apertures becomes significantly more difficult, and even slight deviations can degrade system performance, distort beam profiles, or introduce phase shifts. Optical surfaces must meet extremely high-quality standards at the microscopic scale, as even tiny defects can trigger laser-induced damage at much lower fluence levels.

To address these challenges, optical performance at this scale requires advanced substrate polishing techniques and sophisticated coating processes, such as magnetron or ion beam sputtering.

THE SOLUTION

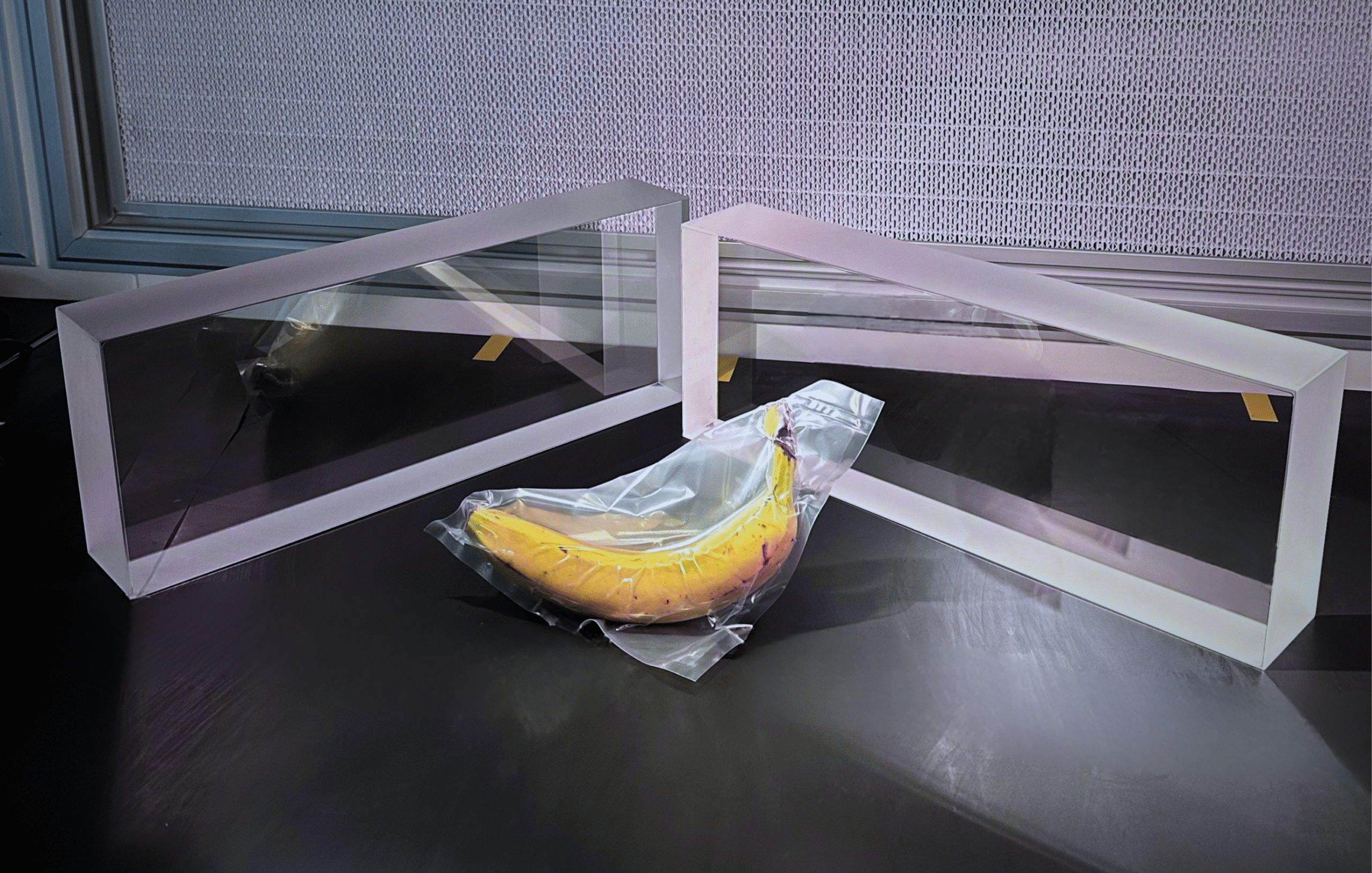

OPTOMAN meets these challenges head-on with one of the largest IBS chambers in the world, capable of manufacturing large diameter laser optics up to ⌀420 mm (banana in the photo for scale).

This machine is named Albert – the Atom Smasher. Equipped with Ion Beam Sputtering (IBS) technology, Albert enables the coating of large diameter optics, with the same exceptional precision, performance, and repeatability that OPTOMAN is known for.

Whether you’re working on high-power, large beam diameter laser systems or mission-critical applications in research, defense, or space, OPTOMAN’s large optics coatings deliver high LIDT, low absorption, and outstanding spectral performance, even at scale.

We don’t just coat large diameter optics. We do it precisely.

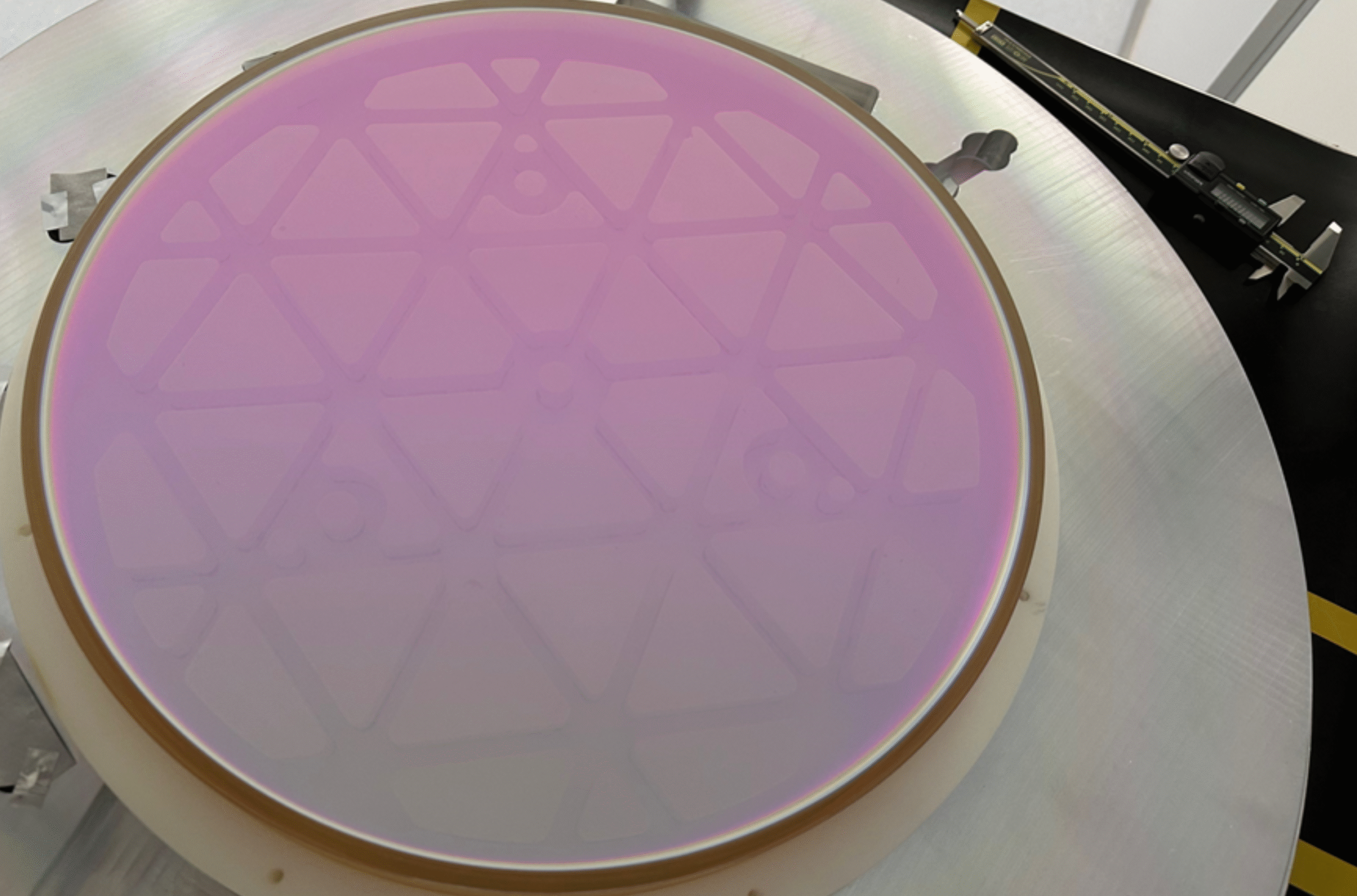

OPTOMAN has already served different scientific and defense industries with its large optics capabilities. In one of the recent large-diameter optics projects (Ø 370 mm), we achieved coating uniformity of ±0.5% across the entire surface, demonstrating not just capability, but consistency of Albert.

- Coating diameter: up to 420 mm*

- IBS-coated for low absorption, high LIDT, and spectral stability

- Ideal for high-power laser systems, beam expanders, and space optics

- Uniformity levels: <±0.5% achievable on full diameter

- Custom coatings design 193 – 5000 nm

*Diameter up to 600 mm is under development

DESIGN EXAMPLES

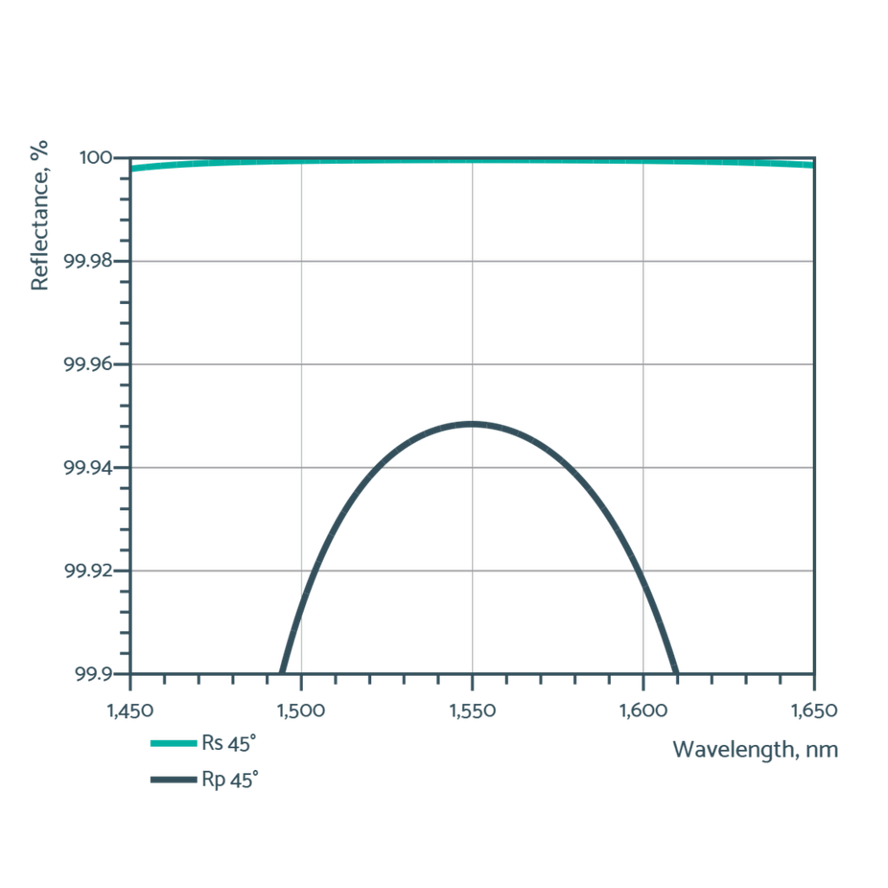

Laser mirror specifically designed for laser space communications.

| Coating specifications: HRs>99.95% & HRp>99.9% @ 1550 nm, AOI=45° |

|

|

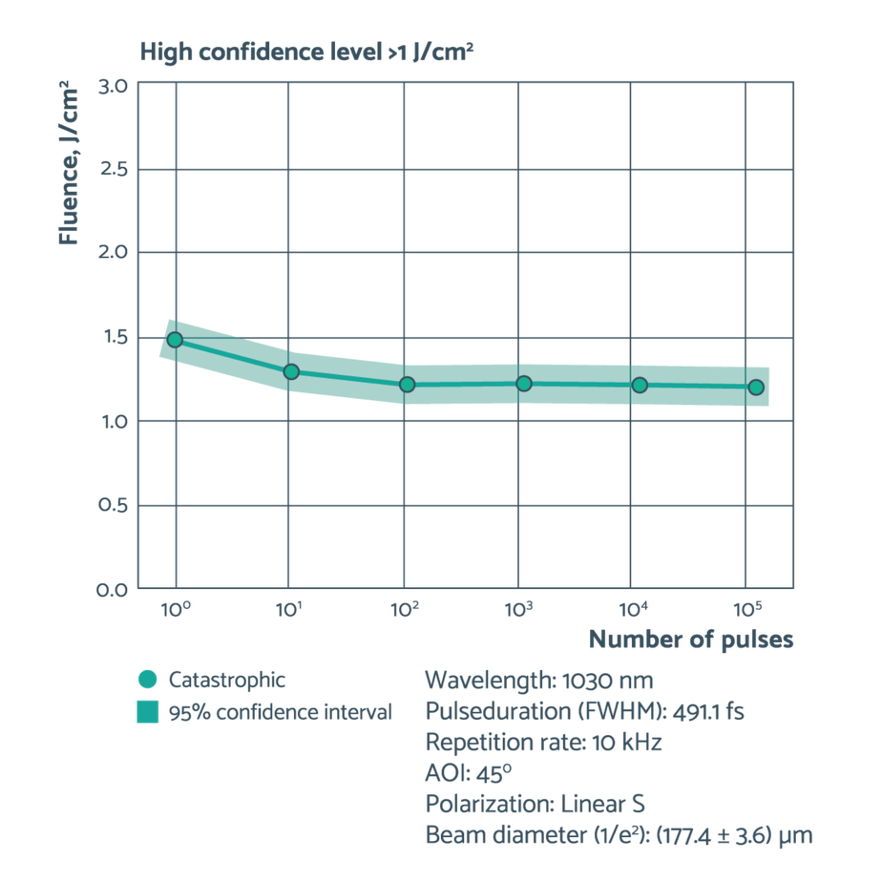

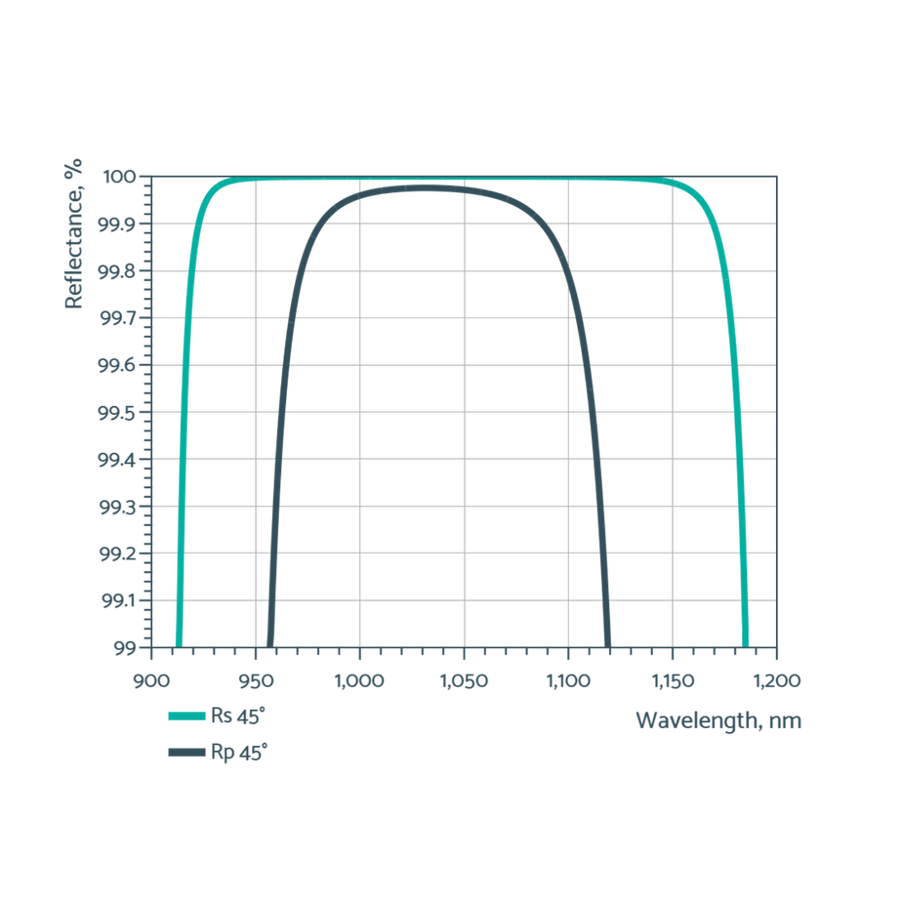

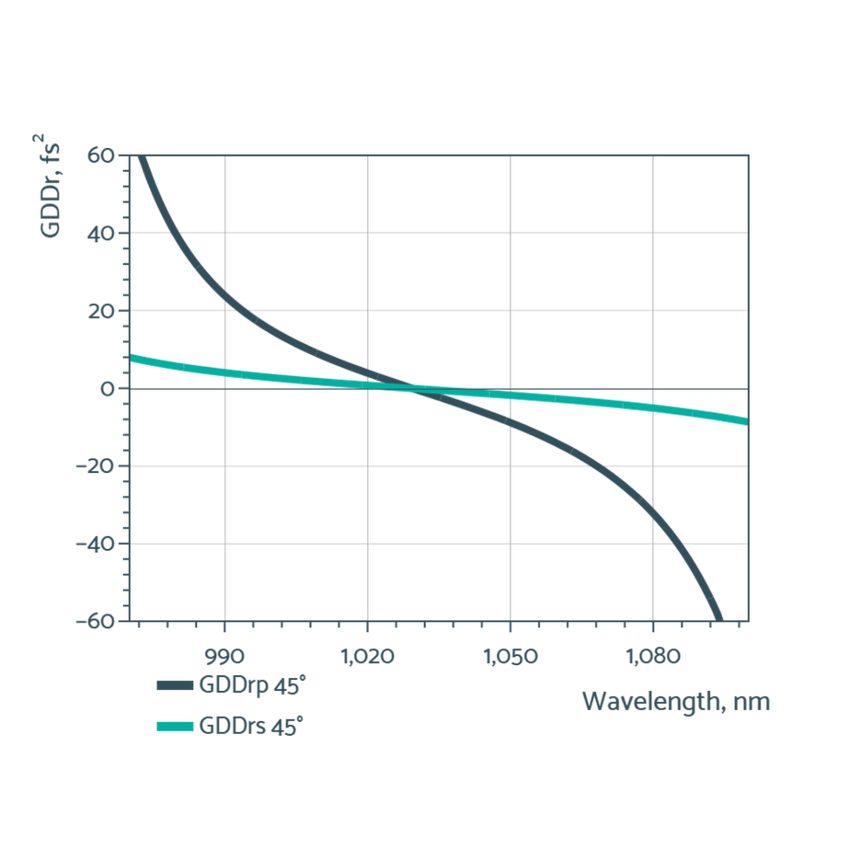

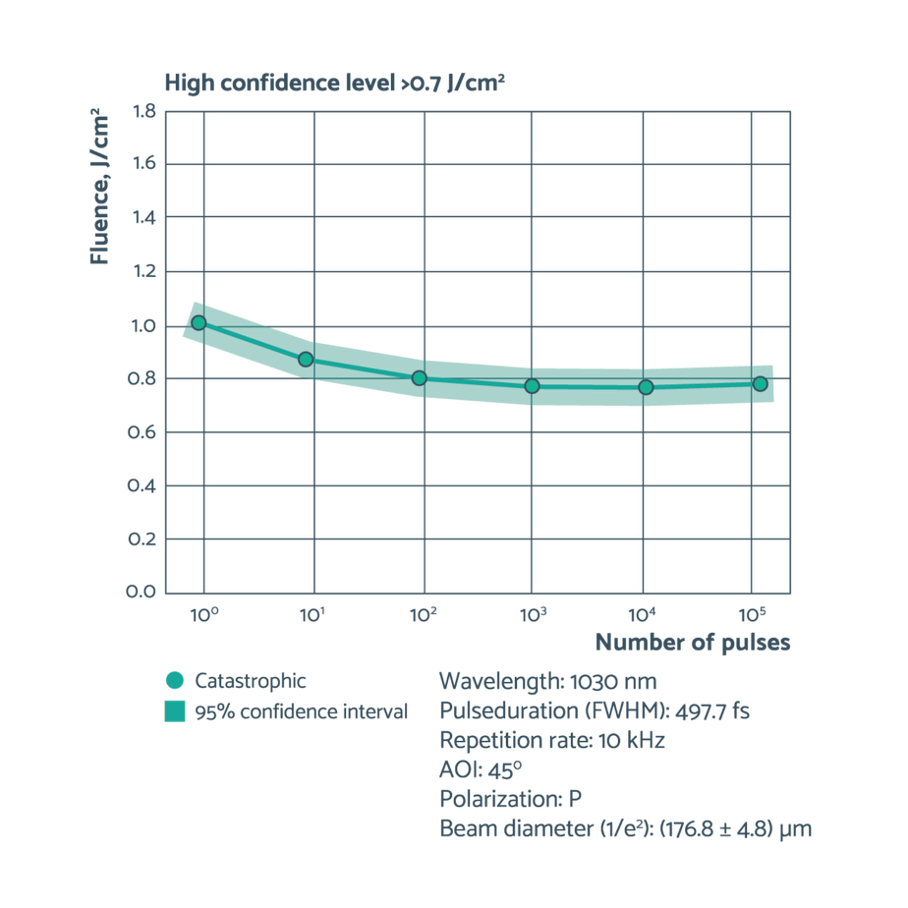

Superhero Power high LIDT mirror for Yb:YAG I harmonic.

Laser-Induced Damage Threshold (LIDT) graphs show no evidence of color change damage.

Coating specifications:

HRs>99.95% & HRp>99.9%@1010 – 1050 nm, AOI=45°

|GDD Rs|<10 fs², |GDD Rp|<20 fs²

|

|

|

Request custom by filling out our contact form.