Low Absorption Protective Windows

Low Absorption Protective Windows are widely used in laser processing to ensure high transmission of laser energy, protect the laser system, and minimise thermal effects.

OPTOMAN protective windows are IBS coated and optimized for high laser power and controlled Z-shift.

OPTOMAN capabilities

- Coating technology – Ion Beam Sputtering (IBS)

Size for round windows: <420 mm, for square windows: 500 x 200 mm

- Surface quality: up to 10-5 S-D (MIL-PRF-13830B)

- Agility, flexibility, and quick prototyping

- High repeatability

Application-optimized products for additive manufacturing, cutting, welding, and drilling

IBS coating

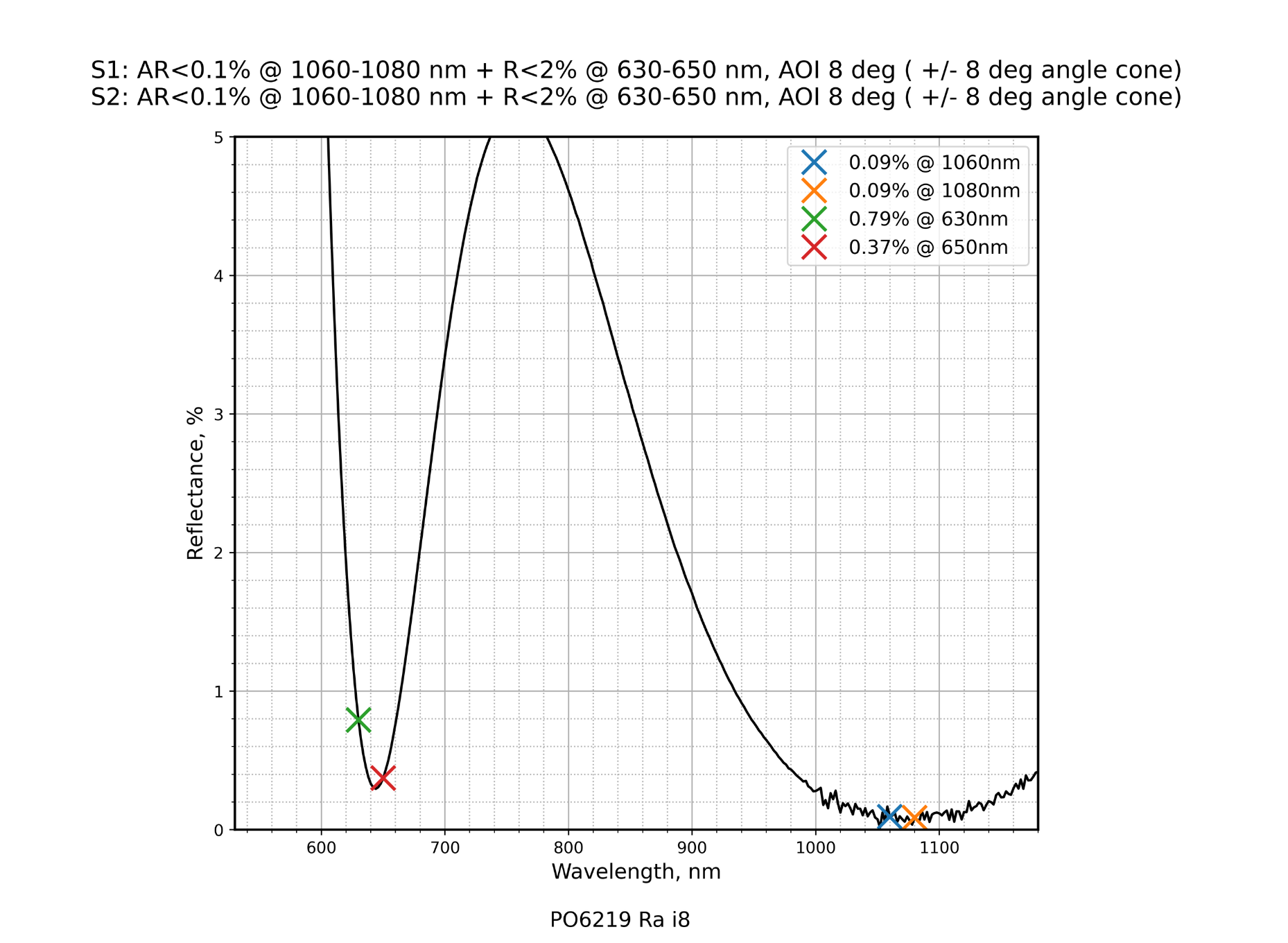

Ra < 0.1 % @ 1060-1070nm + Ra < 2 % @ 633nm

AOI = 8 ± 8° cone

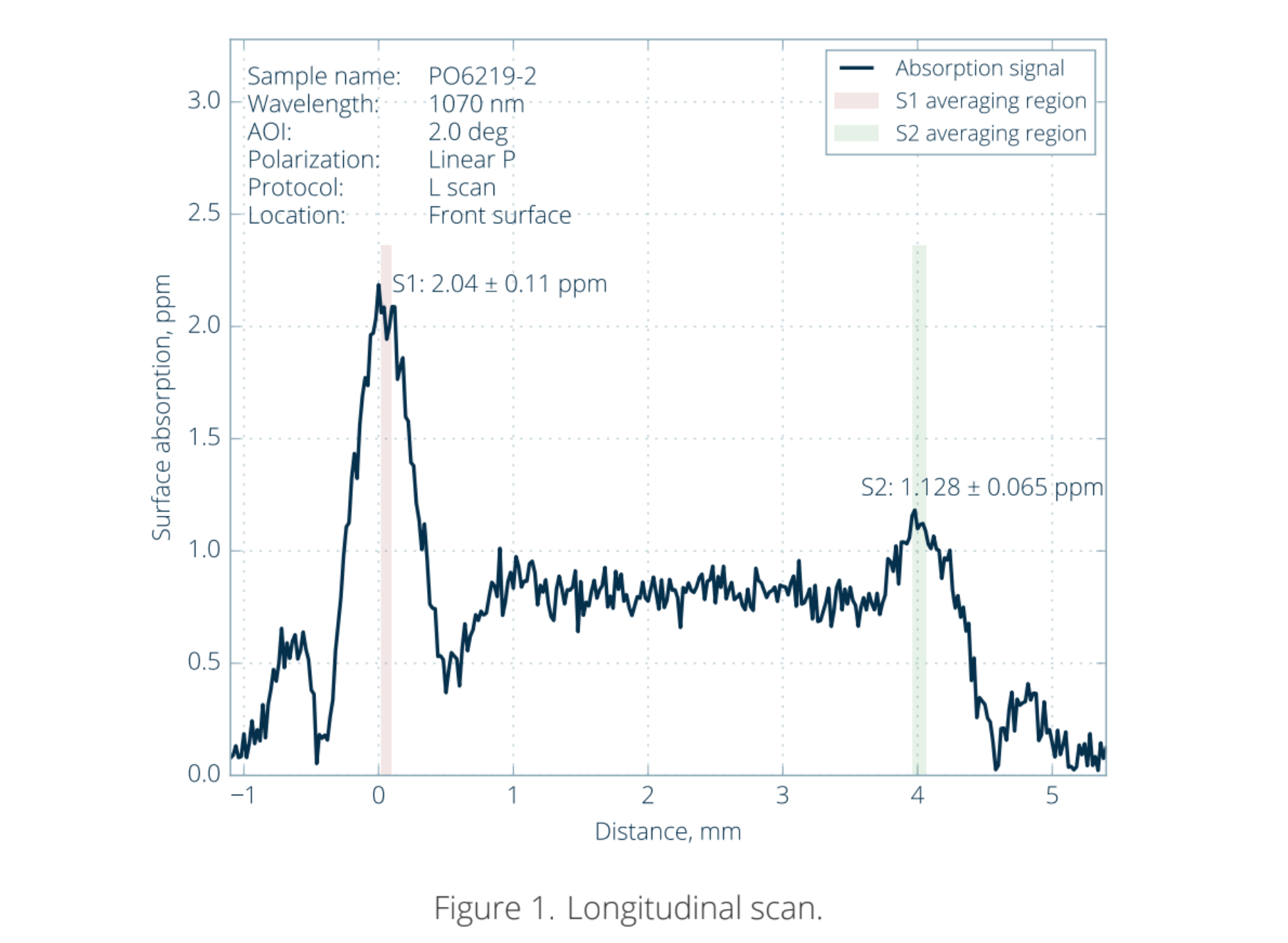

Absorption: <3 ppm

LIDT: >426* kW/cm @ 1070nm, 30s, 137.6 µm

*426 kW was the power limit of the laser

Figure 1. Longitudinal scan.

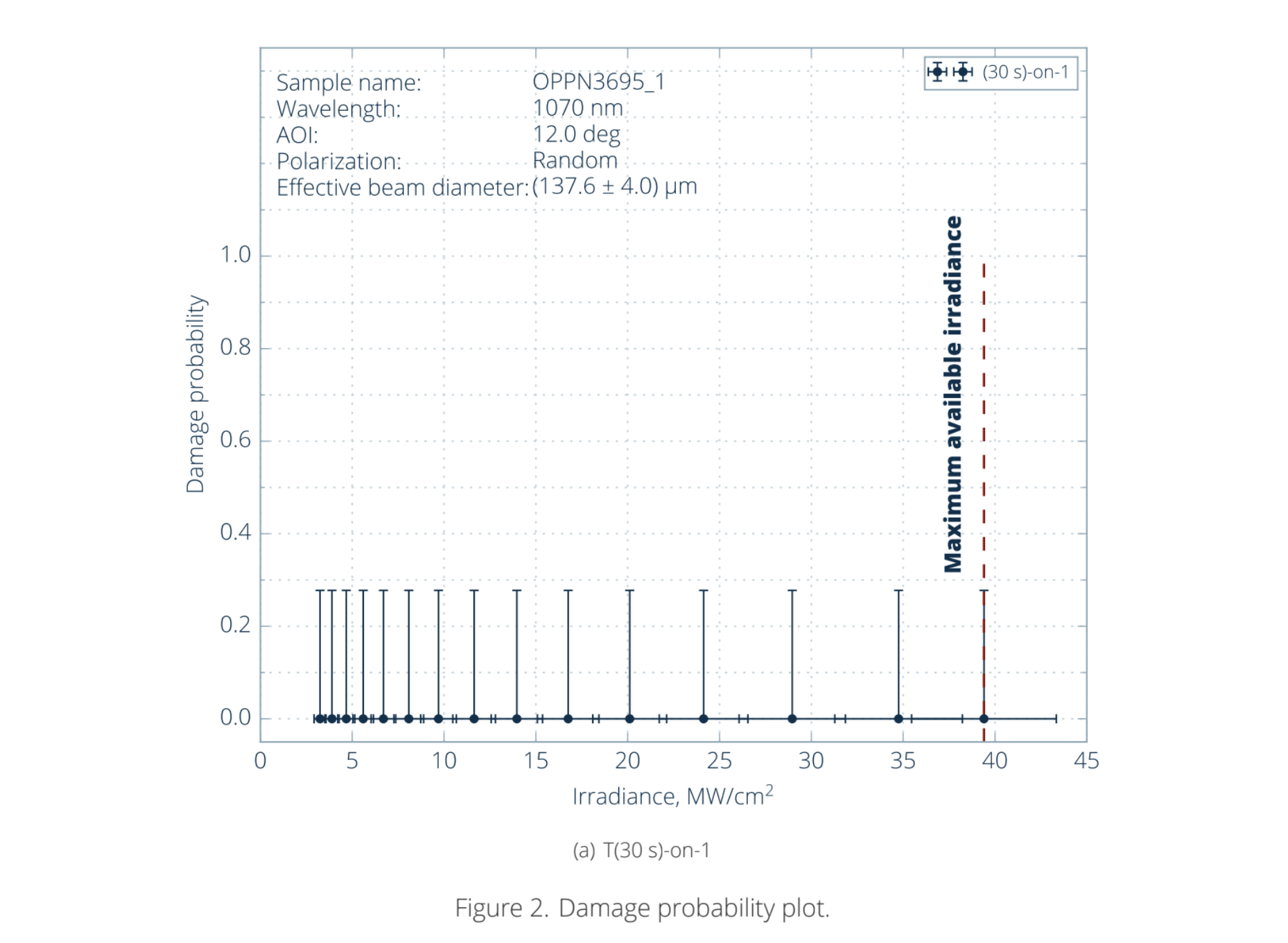

Figure 2. Damage probability plot.