Multiwavelength Low GDD mirrors

- Long lifetime laser optics

- High LIDT coatings featuring high reflectivity up to 99.9%

- Highly customized and application-optimized solutions

| Coating technology | Ion Beam Sputtering (IBS) |

|---|---|

| Spectral range | 193-5000 nm |

| Reflectivity | >99.9% |

| Size | 3-420 mm |

| Flatness | Up to <λ/20 |

| Surface quality | Up to 10-5 S-D over CA (MIL-PRF-13830B) |

| GDD | <20 fs² |

FAQ

How can IBS-coated ultrafast low GDD multiwavelength mirrors benefit my Business?

IBS-coated ultrafast low GDD multiwavelength mirrors are designed to handle multiple wavelengths within a single optical system. These mirrors maintain low group delay dispersion (GDD) across several discrete wavelengths, such as the harmonics of the Yb:YAG laser, while ensuring high reflection values. This capability is crucial for applications where precise pulse control at multiple wavelengths is required. Moreover, broadband configurations can also be achieved for applications that demand even greater flexibility, covering a wide spectral range while maintaining low and spectrally uniform GDD across two or more bandwidths. Lastly, OPTOMAN thrives on achieving high Laser-Induced Damage Threshold (LIDT) and has developed multiwavelength mirrors specifically optimized for femtosecond laser pulses, which reduces the risk of damaging laser optics. Fewer replacements mean less downtime, making these mirrors a cost-effective and reliable choice for high-power multiwavelength laser systems.

At OPTOMAN, our experienced engineers ensure each mirror is finely tuned for your specific application, providing reliable, high-performance laser optics for ultrafast multiwavelength laser systems.

How can I be sure that these mirrors will fit my Business needs?

OPTOMAN digs deep into each application, providing highly customized and application-optimized solutions that will fit your business needs.

Together, we will be able to set the priorities that are most important for your application and needs, whether it is reaching fundamental limitations, proving the concept, or making a well-balanced industrial high runner. We keep an open discussion about the main price drivers and help customers optimize BOM costs while maintaining the highest quality level.

Is it possible to test the optics and how scalable is the production?

Yes. Based on the customer’s presented business case, OPTOMAN, with its R&D-driven attitude and collaborative approach, can design, develop, and manufacture products for testing purposes and present a plan for serial production. Different-size IBS coating chambers are very handy in this case because small-scale production can be easily transferred to our giant IBS machine – Albert (the atom smasher), where we can coat large optics or 400-500 units of 1“ laser optics in a single coating run, ensuring high uniformity, meaning that all mirrors will work the same making your laser systems highly repeatable and reliable too.

Moreover, our in-stock optics marketplace, OPTOSHOP, features over 400 different laser optics made with love by OPTOMAN. These optics can be provided for testing directly from stock and delivered in 1-3 business days. After successful tests, OPTOMAN can present the most optimal production plan matching your business needs.

Does OPTOMAN provide optics or only coating service?

Both. 80% of total OPTOMAN revenue comes from complete products, while 20% is generated by providing coating services on customer-supplied substrates. OPTOMAN responsibly oversees the supplier network for reliable substrates and, if needed, can offer a completely European supply chain.

Does OPTOMAN have available substrates ready to coat?

Yes. OPTOMAN has a number of flat substrates, plano-concave and plano-convex lenses, and spherical mirror substrates in stock, ready to be coated. Choosing the in-stock substrate option allows, on average, saving 6 weeks of lead time and reducing end-product cost 3 times.

Design examples

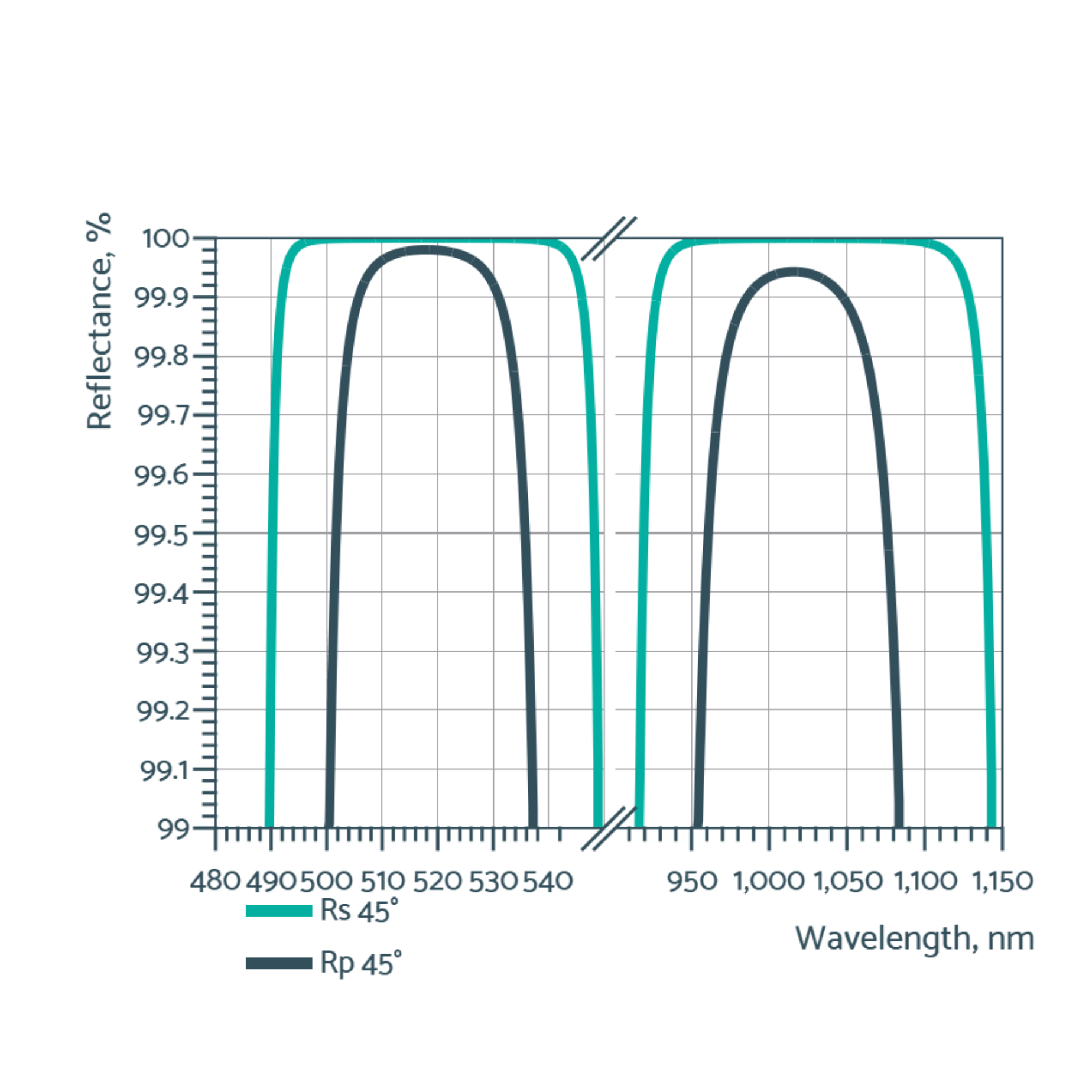

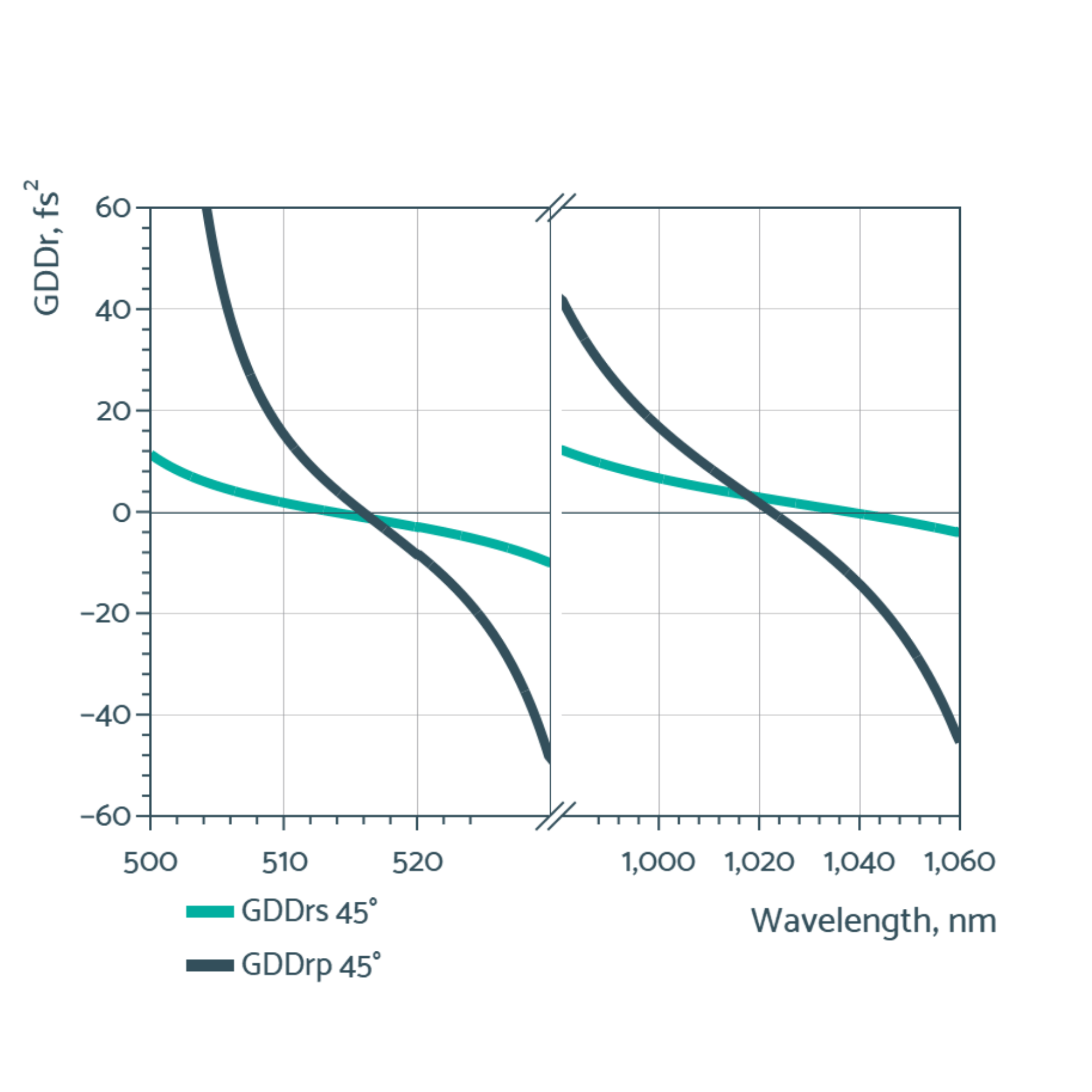

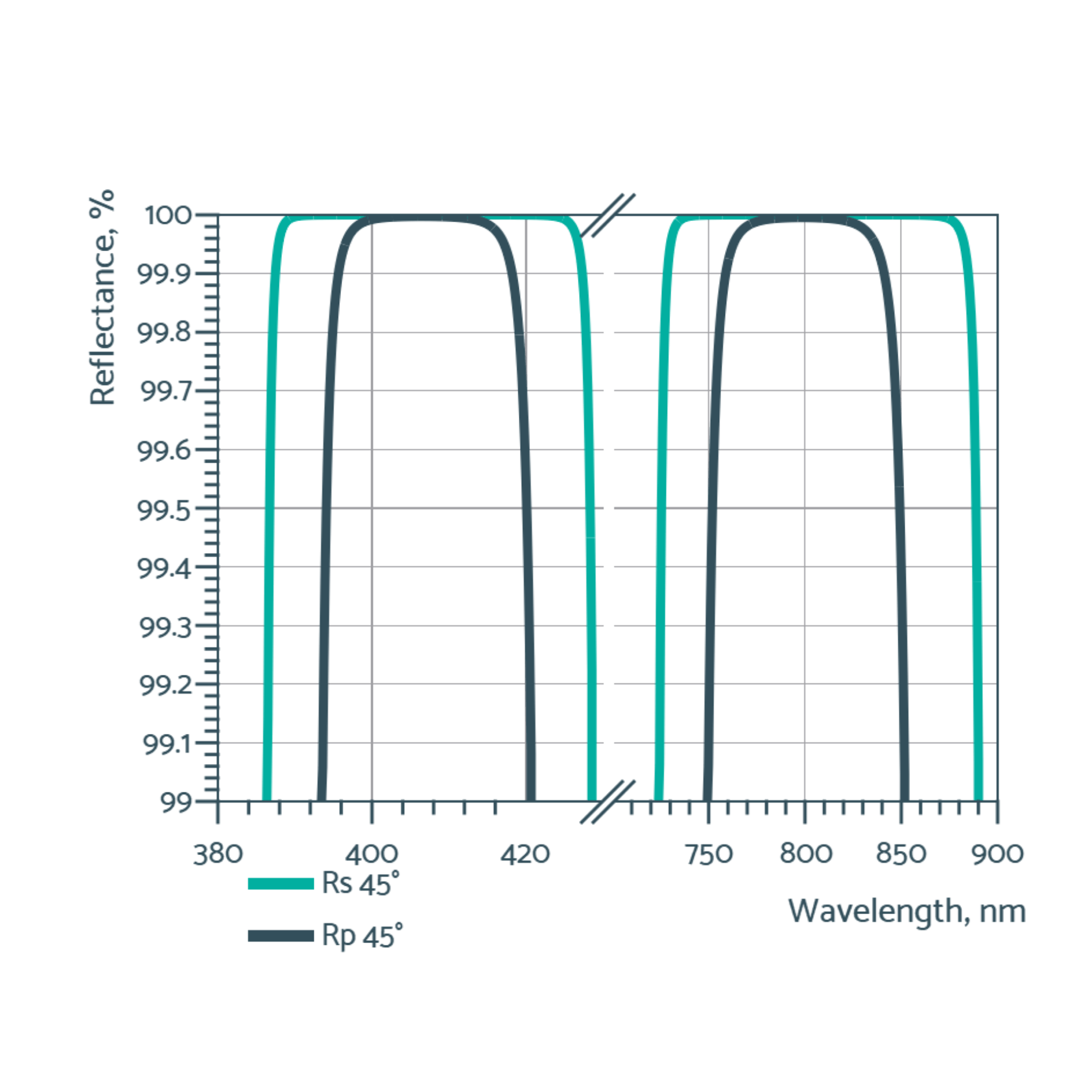

High LIDT Low GDD Multiwavelength mirror for Yb:YAG I and II harmonics.

Coating specifications:

HRsp>99.9% @ 1030 nm & HRsp>99.9% @ 515 nm, AOI=45°

|GDD Rs|<10 fs², |GDD Rp|<20 fs² @ 1030 nm & 515 nm, AOI=45°

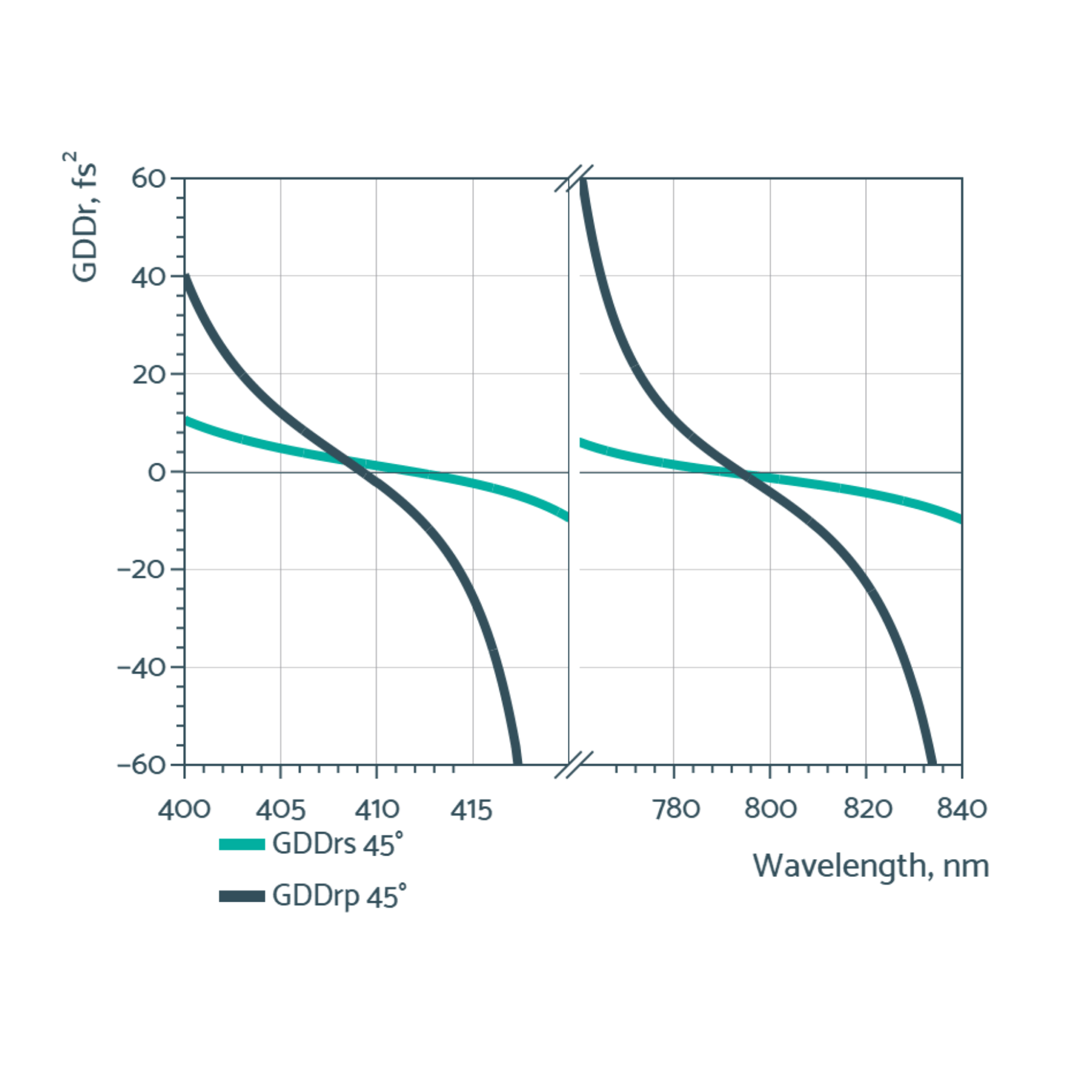

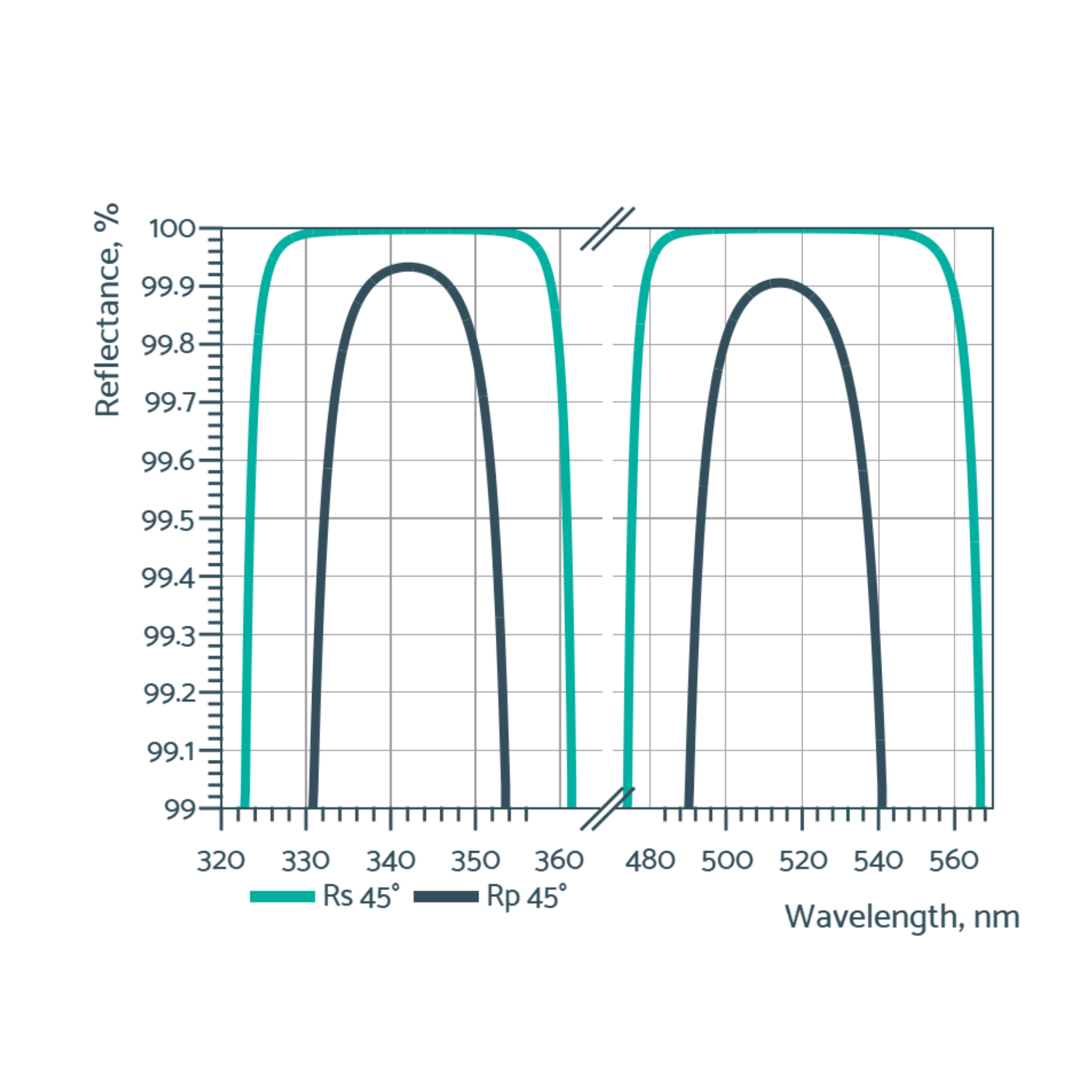

High LIDT Low GDD Multiwavelength mirror for Ti:Sapphire I and II harmonics.

Coating specifications:

HRs > 99.9% @ 385-415 nm + 770-830 nm, AOI=45°

HRp > 99.8% @ 395-415 nm + HRp > 99.9% @770-820 nm, AOI=45°

|GDD(Rs)|<35fs² @ 385-415 nm |GDD(Rp)|<50fs² @ 395-415 nm

|GDD(Rs)|<20fs² @ 770-830nm |GDD(Rp)|<40fs² @ 770-810 nm

High LIDT Low GDD Multiwavelength mirror for Yb:YAG II and III harmonics.

Coating specifications:

HRsp>99.8% @ 343 nm + HRsp> 99.8% @ 515nm, AOI=45°

In-stock products

Fill out a custom request

Relax and build your laser. OPTOMAN has your back.

Thank you

for your request

We will contact you as soon as possible